- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drive technology

Results for

Drive technology - Import export

IGUS® GMBH

Germany

The drive technology online configurator gives you the right drive technology system after you enter your requirements. You also have the option of requesting or ordering motors and other accessories, such as the motor control system. - Fast and easy configuration - Optional accessories - Detailed parts list - Fast delivery

Request for a quote

IGUS® GMBH

Germany

ZLN miniature toothed belt axis based on the low-profile guide system drylin® N. System width 40mm, installation height 28mm. Ready-to-install system with stepper motors or BLDC/DC motors. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

drylin® SLW-1040 linear module, drylin® W aluminium profile, surface: hard-anodised, ball bearing Trapezoidal lead screw TR10x2 made of stainless steel, lead screw end machined 6h9x17mm, guide carriage in 100mm length, shaft end support made of anodised aluminium. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

drylin® SHT-12 linear module, drylin® R hard-anodised aluminium shafts, Trapezoidal lead screw TR10x2 made of stainless steel with ball bearings, machined lead screw ends 6h9x17mm, quad blocks, aluminium shaft end support, stroke lengths in 250mm or 500mm. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

drylin® ZLW-0630 basic toothed belt axis, basic version, feed rate 54mm/rev, aluminium profile, surface: hard-anodised, neoprene toothed belt in black, guide carriage length 60mm, shaft end support made of aluminium, alignment of drive pin on the right, stepper motor with stranded wire. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

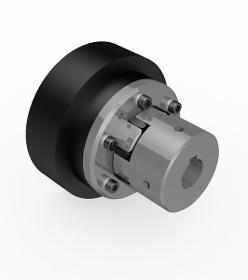

A centrifugal clutch with highly elastic clutch is used for applications where rotating oscillations may occur in addition to the shaft offset. In this case, centrifugal clutches must be used with flange-connected highly-elastic clutch elements. This specifically includes compressor systems and silo vehicles. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch without housing is used when the customer already has a housing. In that case, the centrifugal clutch will be delivered without a bell. A vibration tamper would be one typical application for a centrifugal clutch without a housing. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

In this centrifugal clutch, the output takes place through a sprocket. We offer a broad range of sprockets for this type of centrifugal clutch, including a version ex-stock for cart sports. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

We recommend a centrifugal clutch in combination with an elastic clutch to effectively compensate for the arising shaft offset. This design of a centrifugal clutch is frequently used in pump drives. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

For centrifugal clutches with belt outputs, the belts must be pre-tensioned in order to maintain the pressing force required to transfer force. Usually, tensioning rollers are used in the belt drive for this purpose. However, tensioning rollers are hard to use with short axle distances. The tried-and-tested centrifugal clutch with integrated, automatically acting belt tensioner compensates the length changes of the V-belts by adjusting the diameter of the pulley. Typically, these centrifugal clutches are used in high-quality reversible shaker plates.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with perforation enables customers to attach special output elements, such as sprockets, pulleys and articulated shafts or flanges, etc. This way, the centrifugal clutch can be designed individually and precisely fitting. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with belt output is the most frequently used build of Amsbeck centrifugal clutches. This type of centrifugal clutch has the pulley installed in the clutch bell already. This leads to a compact and space-saving, as well as cost-efficient, build. A centrifugal clutch with belt output can generally use any standardised belt profile and pulley diameter. The number of belt grooves can be chosen freely as well. Of course, a centrifugal clutch with belt output can also be delivered with special belt profiles and V-rib belt profiles at the customer's request. We also offer matching counter-pulleys on request."

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with pulley, like the centrifugal clutch with automatic belt tensioners, offers the benefit of a compact build in which an additional tensioning roller is not needed in the belt drive. In the centrifugal clutch with adjustment disc, the drum is formed as a regulating hub. The regulating hub adjusts the belt pre-tension. The regulating nut is secured with grub screws in the adjustment area and can be set smoothly. These centrifugal clutches are also used in shaker plates.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

We develop and manufacture electric heating components for air conditioners in train systems and shipbuilding as well as preheaters and braking resistors for the drive technology. In the field of separator technology, we manufacture heating elements for the temperature control of different liquids. In all areas we apply the highest standards of high voltage and insulation resistance.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The latest development in lifting platform technology is based on mechanical drive technology using belts. Hydraulic oil is not required. Due to a patented catch system, BELT-LINE meets the safety requirements laid down in DIN EN 1570. The combination of exemplary positioning accuracy, smooth running and long service life is the reason the BELT-LINE is an economical precision solution, and not only for sensitive areas. Exemplary smooth running BELT-LINE convinces with a low noise and harmonious movement sequence, paired with maximum lifting speed and positioning precision. Minimum maintenance time and costs without hydraulic oil In particular in sensitive areas, the robust BELT-LINE technology with its long operating life is the best possible solution. The low-wear components can be quickly replaced due to the modular design. Excellent load change behaviour In the design phase, particular emphasis was placed on developing an excellent load change behaviour. The resilient suspension behaviour is only surpassed by LAWECO push-chain lift platforms.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Customised system or individual part solutions are our core competence at KIS. We develop complete solutions for you based on our own KIS products and combine them with our comprehensive service for drive technology. Whether it's a careful selection of individual components or proper assembly ensuring your application functions perfectly: As bearing specialists based in Germany, we’re there for every step of the process, from development and construction, through monitoring of production and assembly, to quality inspections and practical tests.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

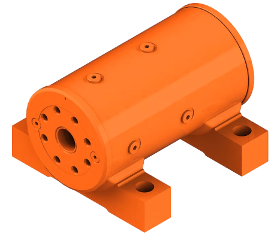

The L-20 series is a particularly cost-effective solution that is suitable for a wide range of applications. It has versatile mounting options and a flange drive. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 4,400 Nm at 210 bar.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-20 series is a particularly cost-effective solution that is suitable for a wide range of applications. It has versatile mounting options and a flange drive. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in five standard sizes with an output torque of up to 4,400 Nm at 210 bar.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The L-30 series consists of our hydraulic drive with helical gearing for heavy-duty applications; it is particularly suitable for harsh environments. The L-30 series is designed for applications requiring extremely high load capacity and is available with a foot or flange mounting option with flange drive. Helac’s sliding spline technology with helical teeth is not self-locking and offers both high impact resistance and a high holding torque for demanding applications. It functions both as a rotating device and as a mounting bracket and support structure, so that no external bearing systems, brakes or locking devices are required. Available in ten standard sizes with an output torque of up to 83,600 Nm at 210 bar.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Large surface area coating can more cost effectively be accomplished using fewer, moving spray guns. Optimize your coating efficiencies with the flexible automation delivered by Venjakob Reciprocators. Nutro, our factory in the USA is the leader in gun drive technology. Large surface area coating can be cost effectively accomplished using fewer, moving spray guns. Products include short-stroke machines equipped with a crank arm type mechanical design (oscillators), most common in powder coating applications. These designs are impractical for long stroke machines (reciprocators) which have used a variety of drive systems including chain driven units, and other electronic systems. Nutro machines are respected for their robust design, high payload capacity and reliability. Since these spray gun drives often support a high payload of guns, hoses and accessories, a heavy duty design is desirable since these machines are often loaded beyond their rated capacity. Nutro’s machines are also cost-efficient and the simplicity of design makes them easy to service. While Nutro has frequently sold spray gun drives to end customers, more commonly Nutro spray gun drives are resold by other OEM manufacturers under a private label arrangement such as Nordson Corporation. Nutro has worked closely with these OEMs to design machines according to their budgets, specifications and preferences. The scope of delivery includes both standard spray gun drives which can be used in series machine lines as well as customer specific machines as required.

Request for a quote

WILHELM MEIER SPINDELN U. DREHTEILE GMBH + CO. KG

Germany

A stem or spindle with a trapezoidal thread is normally used as a movement stem (spindle). We manufacture stems (spindles) from Tr 12 to Tr 110 for drive and actuator technology, for valve construction as well as for power plant, water, waste water and theater technology.

Request for a quoteResults for

Drive technology - Import exportNumber of results

22 Products