- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drive technology

Results for

Drive technology - Import export

IGUS® GMBH

Germany

The drive technology online configurator gives you the right drive technology system after you enter your requirements. You also have the option of requesting or ordering motors and other accessories, such as the motor control system. - Fast and easy configuration - Optional accessories - Detailed parts list - Fast delivery

Request for a quote

IGUS® GMBH

Germany

ZLN miniature toothed belt axis based on the low-profile guide system drylin® N. System width 40mm, installation height 28mm. Ready-to-install system with stepper motors or BLDC/DC motors. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

drylin® SHT-12 linear module, drylin® R hard-anodised aluminium shafts, Trapezoidal lead screw TR10x2 made of stainless steel with ball bearings, machined lead screw ends 6h9x17mm, quad blocks, aluminium shaft end support, stroke lengths in 250mm or 500mm. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

drylin® ZLW-0630 basic toothed belt axis, basic version, feed rate 54mm/rev, aluminium profile, surface: hard-anodised, neoprene toothed belt in black, guide carriage length 60mm, shaft end support made of aluminium, alignment of drive pin on the right, stepper motor with stranded wire. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

drylin® SLW-1040 linear module, drylin® W aluminium profile, surface: hard-anodised, ball bearing Trapezoidal lead screw TR10x2 made of stainless steel, lead screw end machined 6h9x17mm, guide carriage in 100mm length, shaft end support made of anodised aluminium. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

SIKO GMBH

Germany

Magnetic motor feedback systems are proving themselves in numerous applications in linear drive technology, handling systems, circuit board assembly, robotics and in a wide range of automation solutions in the context of Industry 4.0. In all of these areas, the speed and/or position of a drive must be communicated to a main controller in real time. The ultra compact LEC100 and LEC200 sensor duo has been developed by SIKO for these requirements. Repeat accuracy max. ±1 μm. max. resolution 0.2 µm (LD output circuit). Reading distance ≤0.2 mm. Works with MB100/1 magnetic tape. Signal period 1000 μm. Output circuit sin/cos or LD. Function and status display LEDs.

Request for a quote

FÖHRENBACH GMBH

Germany

2-phase stepper motors Our 2-phase stepper motors are reliable and low-cost drives with a long service life. They are available in different sizes and types of power output, are continuously developed and are thus suitable for a variety of applications. AC servo motors The AC servo motors meet the highest demands regarding dynamics and accuracy and are used if dynamic, exact positioning or smooth running characteristics are required. The different types of power output and sizes cover the most diverse requirements. The benefits at a glance Highly dynamic High efficiency Long service life

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

Within the HERMLE range of models, the C 250 is an entry-level model into the world of 5-axis & 5-sided machining. Nevertheless, the “large” models are in no way inferior. Thanks to the large swivelling range of the workpieces in the working area, the utilisation of the complete traverse range and the large collision circle between the table side walls, the C 250 offers the largest working area relative to the installation area. The C 250 is designed for daily use – maximum user-friendliness thanks to pivotable control panel and minimum table distance from the operator and optimum loading height with option ofloading by crane. Maximum precision thanks to the HERMLE swivelling rotary table concept. The table variants of the C 250 therefore stand for the highest quality and optimum use of material – from the cast housing to the installed gear motors: Made in Germany – made in Gosheim.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

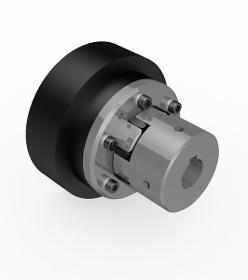

A centrifugal clutch with highly elastic clutch is used for applications where rotating oscillations may occur in addition to the shaft offset. In this case, centrifugal clutches must be used with flange-connected highly-elastic clutch elements. This specifically includes compressor systems and silo vehicles. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch without housing is used when the customer already has a housing. In that case, the centrifugal clutch will be delivered without a bell. A vibration tamper would be one typical application for a centrifugal clutch without a housing. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

In this centrifugal clutch, the output takes place through a sprocket. We offer a broad range of sprockets for this type of centrifugal clutch, including a version ex-stock for cart sports. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

We recommend a centrifugal clutch in combination with an elastic clutch to effectively compensate for the arising shaft offset. This design of a centrifugal clutch is frequently used in pump drives. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

For centrifugal clutches with belt outputs, the belts must be pre-tensioned in order to maintain the pressing force required to transfer force. Usually, tensioning rollers are used in the belt drive for this purpose. However, tensioning rollers are hard to use with short axle distances. The tried-and-tested centrifugal clutch with integrated, automatically acting belt tensioner compensates the length changes of the V-belts by adjusting the diameter of the pulley. Typically, these centrifugal clutches are used in high-quality reversible shaker plates.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with perforation enables customers to attach special output elements, such as sprockets, pulleys and articulated shafts or flanges, etc. This way, the centrifugal clutch can be designed individually and precisely fitting. We generally build two different types of centrifugal clutches: One is the standard clutch with profile hub. The other, for special applications, is the centrifugal clutch in the rotating jaw version. This special centrifugal clutch is outstandingly suitable for applications with high oscillations or very high loads.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with belt output is the most frequently used build of Amsbeck centrifugal clutches. This type of centrifugal clutch has the pulley installed in the clutch bell already. This leads to a compact and space-saving, as well as cost-efficient, build. A centrifugal clutch with belt output can generally use any standardised belt profile and pulley diameter. The number of belt grooves can be chosen freely as well. Of course, a centrifugal clutch with belt output can also be delivered with special belt profiles and V-rib belt profiles at the customer's request. We also offer matching counter-pulleys on request."

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

The centrifugal clutch with pulley, like the centrifugal clutch with automatic belt tensioners, offers the benefit of a compact build in which an additional tensioning roller is not needed in the belt drive. In the centrifugal clutch with adjustment disc, the drum is formed as a regulating hub. The regulating hub adjusts the belt pre-tension. The regulating nut is secured with grub screws in the adjustment area and can be set smoothly. These centrifugal clutches are also used in shaker plates.

Request for a quote

EISELE GMBH

Germany

— Plug connectors series 15 — With shut-off — Can be assembled as bulkhead — Sealing FPM — Material Al natural anodized, brass nickel-plated — Temperature range -20 to +120 °C — Working pressure range -0,8 to 16 bar

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NEUGART GMBH

Germany

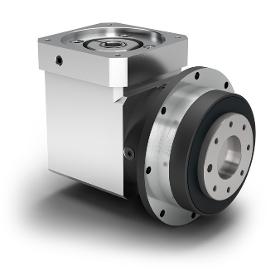

The integrated gearbox/pinion combination provides the best technical coordination for rack and pinion drives. Numerous solution options provide high dynamics and high load-bearing capacities at the same time because of the precision gearing Our WPSFN is extremely light and easy to integrate thanks to its standardized flange interface. It achieves optimized synchronization with the spiral gearing and the helical-toothed planetary stage for the best surface qualities. The shortest right angle precision gearbox with integrated hollow shaft provides you with new structural solutions.

Request for a quote

NEUGART GMBH

Germany

Our PLQE is uncomplicated and powerful. It can be connected directly to your installation without the need for an intermediate flange. The large deep groove ball bearing at the output can absorb large axial and radial forces. In the process, only little heat is generated, so reliable operations are assured even in complex production cycles.

Request for a quote

NEUGART GMBH

Germany

The PFHE represents an economically attractive alternative for high-load applications in which high radial loads occur. The combination of special pre-stressed inclined roller bearings and a flanged output shaft in accordance with EN ISO 9409-1 gives the PFHE a very high load capacity. Thanks to the radial shaft seal that is used, this gearbox achieves protection class IP65 at the output side and can therefore also withstand adverse usage conditions.

Request for a quote

NEUGART GMBH

Germany

AGVs are designed to transport heavy loads on a continuous basis. The specific structural and mechanical demands are extremely high. However, we fulfill them in a reliable way with our NGV planetary gearboxes. Because the gearboxes impress with their compact design, efficiency and durability. And we have specifically optimized them for use in AGVs.

Request for a quote

NEUGART GMBH

Germany

The unique planetary gearbox with certified hygienic design – ideal for reliable cleaning processes. Our HLAE is unique: It is the world’s first planetary gearbox with certified hygienic design – flexible without a radial screw, powerful, and yet ideal for fast and easy cleaning. It has been developed specifically for challenging applications such as in the pharmaceutical, cosmetics, and food industries.

Request for a quote

NEUGART GMBH

Germany

Our PLFN features a standardized flange interface for ease of installation. The straight-teeth precision planetary gearbox has been designed for the highest performance and torque. Its high tilting moment delivers the best performance even under the highest radial and axial forces.

Request for a quote

NEUGART GMBH

Germany

Thanks to its standardized flange interface, our PSFN can be installed easily and reliably. Our Neugart-designed helical teeth makes additional noise absorption measures absolute. Thanks to its high tilting moment, you may demand the utmost from this precision planetary gearbox.

Request for a quote

NEUGART GMBH

Germany

Our PSN embodies pure progress: Its innovative helical teeth safeguard low-noise operations. This precision planetary gearbox minimizes vibrations, and therefore increases the quality of your workpiece surfaces even under the highest bearing loads.

Request for a quote

NEUGART GMBH

Germany

The shortest right angle planetary gearbox with flange output shaft and maximum torsional stiffness. Thinking around corners even in tight spaces. The WPLFE is our right angle planetary gearbox with compact flange output shaft. You save up to 30% more space and benefit from torsional stiffness that is five times higher than conventional products. Thanks to its standardized flange interface, it's especially easy to install. The integrated dowel hole provides additional secureness during fitting.

Request for a quote

NEUGART GMBH

Germany

WPLQE Economy right angle gearbox The WPLQE is our right angle gearbox with the square output flange. This makes it particularly easy to install for a wide range of applications, and its large tapered roller bearings also make it ideal for high radial and axial forces.

Request for a quote

NEUGART GMBH

Germany

The WPLE is a consistent continuation of the benefits offered by the Economy Line. With its compact, but powerful design, it is ideal for dynamic multiple axis systems. Our right angle gearbox features lifetime lubrication, is easy to install, all this at an unrivalled price-performance ratio.

Request for a quote

NEUGART GMBH

Germany

The PLHE is the world’s first combination of economy and precision planetary gearboxes. The prestressed tapered roller bearings of our planetary gearboxes safeguard great stiffness even under the highest loads. The seal we have developed provides the perfect protection against dust and water jets.

Request for a quoteResults for

Drive technology - Import exportNumber of results

121 ProductsCompany type

Category

- Mechanical transmission systems and components (27)

- Clutches (9)

- Gears (7)

- Mechanical transmission - components (5)

- Robotics (5)

- Electric motors and parts (4)

- Handling - Machines & Equipment (4)

- Packing and packaging - machinery and equipment (3)

- Automation - systems and equipment (2)

- Industrial cabling (2)

- Mining and quarrying - machinery and equipment (2)

- Pinions (2)

- Sawing machine tools (2)

- Sensors (2)

- 3D scanner (1)

- Adjustment - machine tools (1)

- Air conditioning equipment (1)

- Bearings - ball, needle and roller (1)

- Dosing pumps (1)

- Electric motors - aC (1)