- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- presses- hydraulic

Results for

Presses- hydraulic - Import export

RUF MASCHINENBAU GMBH & CO. KG

Germany

The RUF briquetting systems of the Biomass series process dust, shavings and wooden chips into briquettes of consistently high quality and density. Varying bulk densities are offset automatically during the process. These materials can be pressed into a compact form without the use of binders. It is important that the moisture content of the chips is below 15%, preferably under 12%, and that the chip size does not exceed 50mm. The general rule is that the finer the material is, the smoother and more solid the surfaces and edges of the resulting briquette. The systems can be equipped with a multitude of options, thus optimally adapting them to customer needs. This series offers maximum flexibility. All systems are extremely energy efficient thanks to the innovative RUF hydraulic system. Depending on the model, the machines are equipped with motors ranging between 4 kW and 90 kW. The throughput capacities of the RUF Biomass presses range between 50 and 1,300 kg/h.

Request for a quote

DELTAFLUID

France

A flow straightener greatly reduces disturbances in a flow while a conditioner reduces disturbances and also allows a good redistribution of the speed profile, at each point of the section of the pipe. Thus, these devices make it possible to reduce the upstream straight lengths and to improve the measurement accuracy in the case of a flow measurement. They are therefore to be positioned between a pipe fitting (elbow, reduction, etc.) and a flow measurement element while respecting the distances specified in the standard.

Request for a quote

DELTAFLUID

France

Different types of pressure transmitters exist: differential pressure transmitter for measuring a pressure difference ΔP but also a relative or absolute pressure transmitter. For more specific applications, it will be necessary to use: a differential pressure transmitter to correct variations of pressure and temperature of a gas two transmitters for the same differential pressure flow element to increase the measuring range For more details on these cases, please see the Frequently Asked Questions tab on this page.

Request for a quote

DELTAFLUID

France

The 1''/1'' flowmeter is also called a flowmeter with flange pressure taps. The high pressure upstream measurement is 1 inch from the upstream edge of the plate and, symmetrically, the low pressure measurement is 1 inch from the downstream edge of the plate. This is often a pre-assembled complete set with orifice plate mounted between orifice flanges. Orifice flanges are standardized and manufactured to ASME B16.36. The orifice plate is manufactured in accordance with ISO 5167 or ASME MFC-3M.

Request for a quote

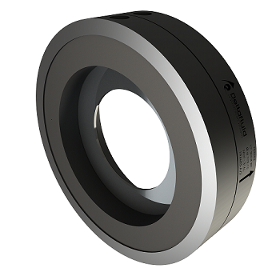

DELTAFLUID

France

The annular chamber (carrier rings) is proposed for orifice plates, for venturis and for nozzles. It has several advantages: it favors the circulation of the fluid over the complete circumference of the pipework and offers a more stable and precise averaged pressure; in the case of the orifice plate, it also allows to change only the plate in case of maintenance or change of process compared to a monoblock where the complete system must be changed. This type of mounting is particularly recommended for pipe diameters smaller than DN50.

Request for a quote

DELTAFLUID

France

For steam applications, condensate pots are essential. They are used to condense the fluid upstream of the differential pressure transmitter. Installed at the same height, they allow accurate measurement by maintaining a constant condensate height in the impulse lines above the differential pressure transmitter. The condensation pot can also be used to protect the transmitter in the case of a flow measurement of a corrosive / aggressive fluid. In this case we speak of separation pots. For more information, see the Frequently Asked Questions tab on this page.

Request for a quote

DELTAFLUID

France

The monoblock diaphragm and the ISA1932 monoblock nozzle are made from a solid round. The pressure taps are directly machined in the monoblock. They can be simply machined (pressure tapping holes) or supplied with nipples to connect directly to your installation. This type of diaphragm or nozzle has the advantage of being simple to install: simply mount it between single flanges or weld directly on the pipe for a version to be welded. All types of edges (sharp-edge, conical, quarter-circle, eccentric, segmental and multi-hole) can be made in a single-piece version. Flanged or corner pressure taps can be made in monoblock version.

Request for a quote

DELTAFLUID

France

According to ISO 5167, flowmeters with orifice plates and nozzles (long radius) can benefit from D - D/2 mounting. This corresponds to a positioning of the upstream tap at a distance of 1D (D, internal diameter of the pipework) from the upstream of the orifice plate and the downstream tap at a distance of 1/2D from the downstream of the plate. This type of assembly has the advantage of not requiring orifice flanges (more expensive than standard flanges): you simply prepare bosses on the piping upstream and downstream of the measurement to position the pressure taps. It is widely used for large pipe diameters.

Request for a quote

REP INTERNATIONAL

France

Machine features : - Closing force: 2,000 kN Application examples: connector technology, pharmaceutical closures.

Request for a quote

IMETA SRL

Italy

In addition to the bare rolls, Imeta offers – as an optional service – the seaming rolls preassembled with their pins and bearings. Seaming rolls are then provided already set and lubricated, ready to be mounted, allowing significantly shortened machine downtimes. The assembly is carried out by our skilled technicians using all the correct tools and equipment such as the hydraulic press and the dynamometric wrench. Potentially using certain old items (pins, bottom plates, dust covers), that maybe still in good condition, it is also possible to provide partial assemblies according to the client’s needs.

Request for a quote

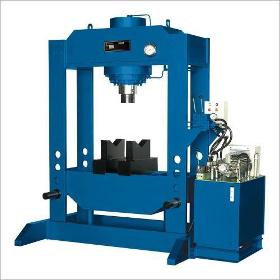

HIDROMEC SRL

Italy

Hydraulic cylinder applications in the stationary industrial sector are diverse: hydraulic presses of all kinds, ranging from presses for sheet metal forming and presses for the plastics industry to filter presses and scrap presses. Roll forming machines are also included, as well as machines and industrial equipment of various kinds. Equipment in constantly changing shapes and sizes gives us the opportunity to apply the design know-how we have acquired over forty years of dedication to meeting a wide variety of customer requirements. Hidromec develops hydraulic cylinders and systems for equipment with applications in the industrial sector that are powerful, durable and comply with the relevant environmental standards.

Request for a quote

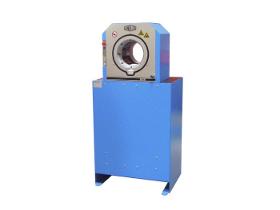

UNIFLEX-HYDRAULIK GMBH

Germany

This hydraulic crimper with patented C-form pressing tool facilitates the radial infeeding of complex hose assemblies. It is particularly well suited for hoses used in automotive manufacturing. * According to the fitting

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

With its distinctive construction and high crimping force of up to 6000 kN, the HM 665 is one of UNIFLEX‘s powerhouses. The HM 665 sets standards for quality and cost effectiveness. Using this model, you can easily crimp up to 12" industrial hoses (depending on the fitting). With long master dies you are able to crimp even long ferrules and sleeves. Quick die change plungers allow for quick die changes even for the larger diameter dies. The fixed six o'clock die eliminates the need to jog the machine to position the assembly for crimping, just lay it on the bottom die and close to crimp.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This machine is not only able to crimp the biggest hoses ever for a UNIFLEX machine, it is also the most compact machine for mobile work in UNIFLEX history. The HMC 12-2000 is the most solidly built C-crimper of the 2000 ton category due to its integrated power booster for high crimping forces. After a long period of research and development in the field of FEM, this machine outshines all others of its category. UNIFLEX defines new crimping techniques and focuses on not only the highest quality and user friendliness but also advanced materials. The strongest C-Crimper for hoses worldwide •C-form crimper with 2000t effective pressforce with UNIFLEX greaseless technology •C-form crimping tool, open on the side, with an 355mm opening - no limit for flanges •Max. crimping range 380mm •For up to 3“ hydraulic / offshore / tubular & 12“ industry hoses •Robust construction for heavy duty •Ideal for special application with its high crimping force

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

We reserve the right to make technical changes without notice. Options are machine parts that can only be ordered while buying the machine. Press designed specifically for the production of automotive hoses. A good example for such a tailor-made solution is the HMC 1-25 and the HMC 1-30 with patented C-shaped crimping tool designed for radial insertion of complex hose lines. This special press is an ergonomically designed, low-noise machine that requires no lubrication. It has been specifically devised for the production of hoses for the automotive industry, offering outstanding press forces and precision. With PFC and other optional features, you can adjust the press force to process materials that are easily damaged, producing strong and lasting connections without any need for gluing, screwing or welding.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNIFLEX-HYDRAULIK GMBH

Germany

Due to their compact, all-round accessible construction, high level of user friendliness, and long service life, the HM4xx set the standard for quality and cost effectiveness. The crimpers‘ particularly large opening stroke and the use of long master dies allow you to crimp all types of fittings and up to 8" industrial hoses.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Service crimper, also available as an ecoline or DC variant. With its crimp force of 2000 kN / 200 t and its crimp range of up to 100 mm, it is designed for crimping hydraulic hose assemblies up to 2” and industrial hose assemblies up to 2”.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

As reliable classic machines, the HM3xx series unites all the outstanding properties of a production crimper. Combining a convincingly solid construction with a high level of user friendliness, and long service life, the HM3xx set a new standard for quality and cost effectiveness. They are compact, powerful and make ergonomic working possible.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Due to their compact, all-round accessible construction, high level of user friendliness, and long service life, the HM4xx set the standard for quality and cost effectiveness. The crimpers‘ particularly large opening stroke and the use of long master dies allow you to crimp all types of fittings and up to 8" industrial hoses.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The perfect calibration press for the pre-assembly of single-piece fittings.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

As the unrivaled classic in the 1¼“ field, with its narrow, innovative construction, high level of user friendliness, versatility and long service life, the machine sets the unbeatable standard for quality and cost effectiveness. The use of solid master dies allows you to crimp all types of fittings with the tried and tested greaseless slide bearing technology, which reduces maintenance costs and increases product quality.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Its compact construction allows for ergonomic working. The use of long master dies allows you to crimp 90° elbow fittings up to 2“ with the tried and tested greaseless slide bearing technology, which reduces maintenance costs and increases the product quality.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

With its distinctive construction and high crimping force of up to 12000 kN, the HM 1200 is one of UNIFLEX‘s powerhouses. The HM 1200 sets the standard for quality and cost effectiveness. Using this model, you can easily crimp up to 10" industrial hoses (depending on the fitting).

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Due to its narrow and innovative construction, high level of user friendliness, and long service life, the HM3H sets new standards for quality and cost effectiveness. Thanks to its compact construction, it allows easy, uncomplicated, and “fast” crimping. The intuitive UNIFLEX Software on the convenient CONTROL C.2 Touch completes the HM3H and ensures product quality.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The hose press S2 is available in various variants, perfectly adapted to your needs: S2 - Standard S2 M H Ecoline - Manual, developed pump S2 M Ecoline - Manual S2 P - Pneumatic S2 A - Automatic S2 DC -different voltages possible The new S2 M Ecoline H helps reduce machine downtimes The S2 M Ecoline crimper from UNIFLEX weighs only 30 kg and is the ideal device for the on-site repair of hydraulic hoses in construction and agricultural machinery. Hose connections up to 1" (for 2-part fittings) or 1 ¼" (for single-part fittings) can be established easily and safely – without the need for lubrication, and protected by a sturdy frame. In high-gear mode, the new two-stage pump of the S2 M Ecoline H line works three times faster than previous models. Thanks to the retractable lever, the compact device takes up only minimum space when stowed away.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Due to their narrow, innovative construction, high level of user friendliness, and long service life, the HM 22x set the standard for quality and cost effectiveness. Their unrivaled accessibility makes ergonomic working possible – optionally from both sides – in production and series manufacture. The tried and tested greaseless slide bearing technology reduces maintenance costs and the strong crimping force of up to 1350 kN crimps widths up to 1“.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

With its crimp force of 2000 kN / 200 t to 2400 kN / 240 t (depending on the Model) and its crimp range of up to 100 mm, it is designed for crimping hydraulic hose assemblies up to 2" and industrial hose assemblies up to 3". This Service crimper is also available as an ecoline or DC variant. * According to the fitting ** Intermediate dies not required *** only with Control B+ Touch

Request for a quoteResults for

Presses- hydraulic - Import exportNumber of results

141 ProductsCountries

Company type

Category

- Presses, hydraulic (58)

- Metal industrial presses (13)

- Bending - steels and metals (9)

- Hydraulic equipment (4)

- Refuse handling - machines and systems (4)

- Forming - steels and metals (3)

- Laser - cutting and welding machines (3)

- Moulding, rubber - machinery (3)

- Bending machine tools (2)

- Coil Springs (2)

- Cylinders, hydraulic (2)

- Folding - steels and metals (2)

- Marble cutting machines (2)

- Metal packaging machine (2)

- SMALL METAL PARTS (2)

- Stamping - steels and metals (2)

- Woodworking - machinery and equipment (2)

- Adjustment - machine tools (1)

- Anti-vibration supports (1)

- Assemblies, hydraulic (1)