TECNO IMPIANTI SRL

Italy

Manufacturer/ Producer

TECNO IMPIANTI SRL

Italy

The cold rolling line mod LLR3560 is equipped with a cold rolling machine with three passes mod TR600/3 and is used for the production of smooth or ribbed wire from 3.5 to 6.0 mm at a max speed of 12 m/sec. The cold rolling line is completed by a vertical uncoiler with two tilting arms for the loading of coils in horizontal, a mechanic descaling machine, a lubricant dispenser, three rolling/profiling cassettes, a spooler. The smooth or ribbed wire produced by the cold rolling line can be collected with horizontal spoolers on fixed reels of 2 or 3 tons, or with single or double vertical spoolers on fixed or collapsible reels of 2 or 3 tons. This cold rolling line can be completed with some accessories: butt-welder, strain-relieving unit with rolls, reel tilting unit, strapping system for the production of strapped wire coils.

Request for a quote

TECNO IMPIANTI SRL

Italy

The cold rolling line mod LLR3580 is equipped with a cold rolling machine with three passes mod TR600/3 and is used for the production of smooth or ribbed wire from 3.5 to 8.0 mm at a max speed of 12 m/sec. The cold rolling line is completed by a vertical uncoiler with two tilting arms for the loading of coils in horizontal, a mechanic descaling machine, a lubricant dispenser, three rolling/profiling cassettes, a spooler. The smooth or ribbed wire produced by the cold rolling line can be collected with horizontal spoolers on fixed reels of 2 or 3 tons, or with single or double vertical spoolers on fixed or collapsible reels of 2 or 3 tons. This cold rolling line can be completed with some accessories: butt-welder, strain-relieving unit with rolls, reel tilting unit, strapping system for the production of strapped wire coils.

Request for a quote

TECNO IMPIANTI SRL

Italy

The cold rolling line Mod LLR4010 is utilized for production of smooth and ribbed wire with finished diameter 4,0 – 10,0 mm., at a maximum working speed of 12,0 mt/sec. Inside one single structure there are installed the mechanical descaler, the lubricant dispenser, the cold rolling cassettes, the vertical bullblock with 2 passes, the strain relieving device. The descaling unit Mod. DM14 is equipped with 6 rolls with insert in tungsten carbide, an air-blower and a tank for collection of the scales. The lubricant dispenser Mod. DL14 has two cochleas, one vertical and one horizontal. The cold rolling cassettes Mod. CRC150-30-33 are strong-built and do not require an axial regulation of every single roll because the very close tolerances of every single components of the cassettes guarantee the auto-alignment. The vertical bullblock Mod. MV14 can work with one or two passes. The double pass is necessary to obtain the diameter 4.00 mm.

Request for a quote

TECNO IMPIANTI SRL

Italy

The cold rolling line Mod LLR4012 is utilized for production of smooth and ribbed wire with finished diameter 4,0 – 12,0 mm., at a maximum working speed of 12,0 mt/sec. Inside one single structure there are installed the mechanical descaler, the lubricant dispenser, the cold rolling cassettes, the vertical bullblock with 2 passes, the strain relieving device. The descaling unit Mod. DM14 is equipped with 6 rolls with insert in tungsten carbide, an air-blower and a tank for collection of the scales. The lubricant dispenser Mod. DL14 has two cochleas, one vertical and one horizontal. The cold rolling cassettes Mod. CRC150-30-33 are strong-built and do not require an axial regulation of every single roll because the very close tolerances of every single components of the cassettes guarantee the auto-alignment. The vertical bullblock Mod. MV14 can work with one or two passes. The double pass is necessary to obtain the diameter 4.00 mm.

Request for a quote

TECNO IMPIANTI SRL

Italy

The cold rolling line mod LLR6014 is equipped with an horizontal bullblock with one pass and is used for the production of smooth or ribbed wire from 6.0 to 14.0 mm at a max speed of 8 m/sec. The cold rolling line is completed by a vertical uncoiler with two tilting arms for the loading of coils in horizontal, a mechanic descaling machine, a lubricant dispenser, a rolling/profiling cassette, a spooler. The smooth or ribbed wire produced by the cold rolling line can be collected with horizontal spoolers on fixed reels of 2 or 3 tons, or with single or double vertical spoolers on fixed or collapsible reels of 2 or 3 tons. This cold rolling line can be completed with some accessories: butt-welder, strain-relieving unit with rolls, reel tilting unit, strapping system for the production of strapped wire coils.

Request for a quote

TECNO IMPIANTI SRL

Italy

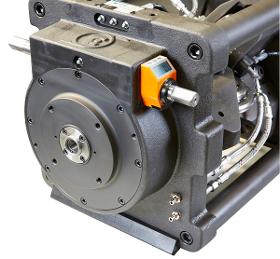

The cold rolling cassettes Mod CRC are utilized for executing the rolling and profiling operations on the wire, for production of smooth and ribbed wire. Strongly-built and innovative in their design, they permit to reduce the time needed for installing the rolls. These cassettes do not require an axial regulation of every single roll because the very close tolerances of every single components of the cassettes guarantee the auto-alignment. By having one set of cassettes in operation and a second set off-line, being prepared with the rolls for the next application, the downtimes are reduced. When a production change is needed, the operator just removes the first set of cassettes from the cold rolling line, replaces them with the second set and start immediately to work.

Request for a quote

TECNO IMPIANTI SRL

Italy

Tecno Impianti designs and manufactures mechanical descalers Mod. DM which are utilized for descaling the wire before the it is processed on our cold rolling lines. Our mechanical descalers are available in different configurations, according to the wire diameter and the application which has to be run. The descaling rolls are manufactured in tungsten carbide.

Request for a quote

TECNO IMPIANTI SRL

Italy

After the descaling operation, the wire passes through a lubricant dispenser. Tecno Impianti designs and manufactures the lubricant dispenser Mod. DL in the version with two screws for high speed cold rolling lines.

Request for a quote

TECNO IMPIANTI SRL

Italy

On our cold rolling lines, at the exit of the last pass, before the wire is taken-up on the vertical or horizontal spoolers, it is possible to install a strain relieving unit with rolls, Mod. SR. The strain relieving units with rolls manufactured by Tecno Impianti are available in different configurations, according to the type of cold rolling line on which they are installed.

Request for a quote

TECNO IMPIANTI SRL

Italy

Unlocking the roll-holders nut is not an easy thing to do. The unlocking device Mod. DSR is very useful and practical and is of great help to the operator.

Request for a quoteManufacturer/ Producer

Via Postale Vecchia, 67

23857 Valgreghentino - Italy

europages also recommends

A selection of companies related to the activity:

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free