- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cleaning- industrial

Results for

Cleaning- industrial - Import export

WOMA GMBH

Germany

With up to 95°C façades, small pipes, industrial flooring and other surfaces can be easily cleaned, oil and grease can be washed away and coating can be removed. The compact and light singleaxle trailer can be brought to site with almost any middle class car. The easy to understand WOMATIC 4Control with operational status monitoring, pressurerpm regulation and pressureless circulation ensures high operational safety, low wear and tear, long service life, and last but not least, minimal fuel consumption. The tank system with 5 chambers including a safety trough hinders operational fluids escaping, such as fuel, oil or softeners.

Request for a quote

WOMA GMBH

Germany

With up to 95 °C façades, small pipes, industrial flooring and other surfaces can be easily cleaned, oil and grease can be washed away and coating can be removed. The compact and light singleaxle trailer can be brought to site with almost any middle class car. The easy to understand WOMATIC 4Control with operational status monitoring, pressurerpm regulation and pressureless circulation ensures high operational safety, low wear and tear, long service life, and last but not least, minimal fuel consumption. The tank system with 5 chambers including a safety trough hinders operational fluids escaping, such as fuel, oil or softeners.

Request for a quote

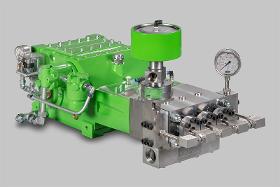

KAMAT GMBH & CO. KG

Germany

The K18000-3G triplex plunger pump has forced lubrication, making it ideal for continuous operation. Its main application is industrial cleaning. For large ship areas it is advisable to combine the pump with the Magnet Crawler (Ship Hull Crawler) from the Gekko range. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature. - Minimum inlet pressures dependent on fluid being pumped - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Forced lubrication gearbox (> 130 kW with oil cooler) - Standard gear ratios i = 3,00 - 3,14 - 3,39 - 3,76 - 4,13 - 4,50 - 4,93 - Can also be operated vertically - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request

Request for a quote

JETCLEAN GMBH

Germany

The complexity of hydraulic systems is continually increasing. As a result, the purity of the installed components is becoming more and more significant. This applies not only to pumps and valves, but also to the pressure lines that connect them. The ptcsystem® is easy to handle. It provides effective protection against initial damage and premature component wear. Compressed air at a pressure of 6-8 bar is used to route a cleaning projectile through the lines needing to be cleaned. The cleaning of complex bending geometries is possible. The chrome-plated launcher made of high-strength aluminium is an extremely durable tool, even under the toughest working conditions. Using a balancer, it can be hung up such that it is always ready to hand. With its ergonomically designed handle and rotatable compressed air connection, the ptcsystem® launcher is also suitable for cleaning small product series.

Request for a quote

JETCLEAN GMBH

Germany

The FERRET pipe cleaning machine is a user-friendly and handy tool for cleaning horizontal and vertical flue gas pipes. This eliminates the need for strenuous cleaning with brushes on a rod or awkward fiddling with rotating shafts. This significantly reduces the cleaning time. The FERRET machine is driven pneumatically. The oscillating brush propels the machine forward automatically and ensures an excellent cleaning result. Air consumption is low. A work area of approx. 0.5 m in front of the boiler is more than sufficient. Use the FERRET machine to clean your flue gas pipes up to a residual temperature of 150 °C. The use of special vacuum cleaner nozzles means that work is carried out virtually dust-free.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Single and multi-stage spray chamber washing systems for industrial cleaning and degreasing of tools and parts. Loading takes place via an extendable loading platform at ergonomic working height. Before cleaning, the loading basket is loaded and moved into the rinsing chamber. The individual stainless steel washing nozzles can be easily maintained and adjusted according to the application. The motor-driven spraying rotor completely revolves around the loaded parts. The washing system is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

IGUS® GMBH

Germany

EasyChains® are available in two versions. In the "E" version the cable is simply laid from the outside, and in the "Z" version from the inside. The shortened installation time is one of the main features of the Easy Chain® chains. Their elastic and rugged material igumid NB offers even more reasons for application: Optimum elasticity, UL94-V2 Classification and excellent suitability for clean rooms. Their one-piece design makes EasyChain® especially attractive in price. Due to the lower rigidity of the material, the EasyChain® is not suitable for applications with very high load. New: Now as ESD option Easy Chain® as ESD Overview for easy chain® advantages Further information Series E03 Inner height hi: 5 mm Inner widths Bi: 5 - 10 mm bending radii R: 10 - 28 mm Pitch: 10 mm E-Chain®, to be filled in the outer radius Series E04 Inner height hi: 7 mm Inner width Bi: 7 mm Bending radii R: 15 - 48 mm Pitch: 16.7 mm E-Chain®, to be filled in the outer radius Series E045 Inner height hi: 9.4 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the outer radius Series E045.2 Innerheight hi: 9,4 mm inner width Bi: 7+7 mm | 9+9 mm Bending radii R: 18 - 38 mm Pitch; 13 mm E-Chain®, to be filled in the outer radius Series E045.3 Inner height hi: 9,4 mm Inner width Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the outer radius Series E06 Inner height hi: 10,5 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 20 mm E-Chain®, to be filled in the outer radius Series E065 Inner height hi: 11,3 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.2 Inner height hi: 11,3 mm Inner width Bi: 9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.3 Inner height hi: 11,3 mm Inner width Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.4 Inner height hi: 11,3 mm Inner width Bi: 9+9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E08 Inner height hi: 14,6 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, to be filled in the outer radius Series E14 Inner height hi: 19 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the outer radius Series E200 Inner height hi: 24.3 mm Inner width Bi: 57 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the outer radius Series E200.2 Inner height hi: 24.3 mm Inner widths Bi: 37+37/50+50 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the outer radius Series E16 Inner height hi: 32 mm Inner widths Bi: 23 - 100 mm bending radii R: 60 - 100 mm Pitch: 30,5 mm E-Chain®, to be filled in the outer radius Series E26 Inner height hi: 36.5 mm Inner width Bi: 75 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E26.2 Inner height hi: 37.1 mm Inner width Bi: 48+48 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E26.3 Inner height hi: 37.1 mm Inner width Bi: 47+48+47 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E300 Inner height hi: 48,5 mm Inner width Bi: 75 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series E300.2 Inner height hi: 48.5 mm Inner width Bi: 48+48 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series E300.3 Inner height hi: 48.5 mm Inner width Bi: 47+46+47 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series Z045 Inner height hi: 9.4 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the inner radius Series Z045.2 Inner height hi: 9,4 mm Inner width Bi: 7+7 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the inner radius Series Z06 Inner height hi: 10,5 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 20 mm E-Chain®, to be filled in the inner radius Series Z065.3 Inner height hi: 11.3 mm Inner widths Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the inner radius Series Z08 Inner height hi: 14,7 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, to be filled in the inner radius Series Z14 Inner height hi: 19 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the inner radius Series Z200 Inner height hi: 24.3 mm Inner width Bi: 57 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the inner radius Series Z200.2 Inner height hi: 24.3 mm Inner widths Bi: 37+37/50+50 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the inner radius Series Z16 Inner height hi: 32 mm Inner widths Bi: 23 - 100 mm bending radii R: 40 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the inner radius Series Z26 Inner height hi: 36.5 mm Inner width Bi: 75 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z26.2 Inner height hi: 37.1 mm Inner width Bi: 48+48 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z26.3 Inner height hi: 37.1 mm Inner width Bi: 47+48+47 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z300 Inner height hi: 48,5 mm Inner width Bi: 75 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Series Z300.2 Inner height hi: 48.5 mm Inner width Bi: 48+48 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Series Z300.3 Inner height hi: 48.5 mm Inner width Bi: 47+46+47 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Certificate IPA: standard material ISO Class 2 according to ISO 14644-1, v = 1 m/s UL94-V2 classification Rotary movement possible Easy Chain® with special material igumid ESD as electrically conductive ESD/TEX option available on request EasyChains® are available in two versions. In the "E" version the cable is simply laid from the outside, and in the "Z" version from the inside. The shortened installation time is one of the main features of the Easy Chain® chains. Their elastic and rugged material igumid NB offers even more reasons for application: Optimum elasticity, UL94-V2 Classification and excellent suitability for clean rooms. Their one-piece design makes EasyChain® especially attractive in price. Due to the lower rigidity of the material, the EasyChain® is not suitable for applications with very high load. New: Now as ESD option Easy Chain® as ESD Overview for easy chain® advantages Further information Series E03 Inner height hi: 5 mm Inner widths Bi: 5 - 10 mm bending radii R: 10 - 28 mm Pitch: 10 mm E-Chain®, to be filled in the outer radius Series E04 Inner height hi: 7 mm Inner width Bi: 7 mm Bending radii R: 15 - 48 mm Pitch: 16.7 mm E-Chain®, to be filled in the outer radius Series E045 Inner height hi: 9.4 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the outer radius Series E045.2 Innerheight hi: 9,4 mm inner width Bi: 7+7 mm | 9+9 mm Bending radii R: 18 - 38 mm Pitch; 13 mm E-Chain®, to be filled in the outer radius Series E045.3 Inner height hi: 9,4 mm Inner width Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the outer radius Series E06 Inner height hi: 10,5 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 20 mm E-Chain®, to be filled in the outer radius Series E065 Inner height hi: 11,3 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.2 Inner height hi: 11,3 mm Inner width Bi: 9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.3 Inner height hi: 11,3 mm Inner width Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.4 Inner height hi: 11,3 mm Inner width Bi: 9+9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E08 Inner height hi: 14,6 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, to be filled in the outer radius Series E14 Inner height hi: 19 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the outer radius Series E200 Inner height hi: 24.3 mm Inner width Bi: 57 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the outer radius Series E200.2 Inner height hi: 24.3 mm Inner widths Bi: 37+37/50+50 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the outer radius Series E16 Inner height hi: 32 mm Inner widths Bi: 23 - 100 mm bending radii R: 60 - 100 mm Pitch: 30,5 mm E-Chain®, to be filled in the outer radius Series E26 Inner height hi: 36.5 mm Inner width Bi: 75 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E26.2 Inner height hi: 37.1 mm Inner width Bi: 48+48 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E26.3 Inner height hi: 37.1 mm Inner width Bi: 47+48+47 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E300 Inner height hi: 48,5 mm Inner width Bi: 75 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series E300.2 Inner height hi: 48.5 mm Inner width Bi: 48+48 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series E300.3 Inner height hi: 48.5 mm Inner width Bi: 47+46+47 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series Z045 Inner height hi: 9.4 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the inner radius Series Z045.2 Inner height hi: 9,4 mm Inner width Bi: 7+7 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the inner radius Series Z06 Inner height hi: 10,5 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 20 mm E-Chain®, to be filled in the inner radius Series Z065.3 Inner height hi: 11.3 mm Inner widths Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the inner radius Series Z08 Inner height hi: 14,7 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, to be filled in the inner radius Series Z14 Inner height hi: 19 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the inner radius Series Z200 Inner height hi: 24.3 mm Inner width Bi: 57 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the inner radius Series Z200.2 Inner height hi: 24.3 mm Inner widths Bi: 37+37/50+50 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the inner radius Series Z16 Inner height hi: 32 mm Inner widths Bi: 23 - 100 mm bending radii R: 40 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the inner radius Series Z26 Inner height hi: 36.5 mm Inner width Bi: 75 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z26.2 Inner height hi: 37.1 mm Inner width Bi: 48+48 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z26.3 Inner height hi: 37.1 mm Inner width Bi: 47+48+47 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z300 Inner height hi: 48,5 mm Inner width Bi: 75 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Series Z300.2 Inner height hi: 48.5 mm Inner width Bi: 48+48 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Series Z300.3 Inner height hi: 48.5 mm Inner width Bi: 47+46+47 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining, separating and filling of the Easy Chain®. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. Easy Chain® Easy Chain: "E" and "Z" makes it "Easy" Easily fillable from the inside (Z version) and outside (E version) Quicker filling, access to cables without opening or closing of the lids Can be put together or taken apart at "any point" Cost-effective, one-piece chain Dirt-proof outer contour Mounting brackets with integrated strain relief available Limited torsional movement possible Available with interior separation (many types) Flammability class UL94-V2 Suitable for clean room applications Typical industrial sectors and applications General machinery Clean room application Electronic equipment Office furniture Vending machines Packaging machines Certificate IPA: standard material ISO Class 2 according to ISO 14644-1, v = 1 m/s UL94-V2 classification Rotary movement possible Easy Chain® with special material igumid ESD as electrically conductive ESD/TEX option available on request

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Service Cleaning: Our customers count on our contract cleaning team for their daily cleaning needs -. With modern cleaning processes e.g. thermal with pyrolysis, aqueous with ultrasonic or mechanical with lapping blasting we can clean and improve your high quality tools. Whether extrusion or injection molding tools, extruder screws, hot runners, nozzles, filters, molds, screens, adhesive or coating devices - everything will be cleaned by us for you! Detailed advice and documented cleaning of samples ensure consistent results over a long period of time. Test us - In addition to comprehensive advice, we offer you the opportunity to carry out your own cleaning trials of workpieces up to a length of 3 m and / or 4 t in weight. Cleaning trials: Every customer can convince himself of our offer by a free sample cleaning. Whether cleaning, surface treatment or decoating - with us you as a customer can see the result even before the first order!

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® MT micro blasters are used for precise blasting with blasting nozzles from 0.4 – 1.8 mm. Surfaces can be smoothed, matted, deburred or cleaned. All mineral media, e.g. glass beads, broken glass, corundum, silicon carbide in the grain size range from 0 to 300 mμ serve as blasting media. The abrasive is used only once. The blasted surface is reproducible. Only a compressed air connection is required to operate the equipment. Micro-Tip fine blast units are suitable as portable free blast units or in combination with a blast cabinet. Micro-Tip fine blasting technology is available as a pressure or injector process. All units are equipped with foot pedal, pressure regulator, manometer and carbide nozzles.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® CORUS HD ultrasonic systems have been specially designed for cleaning high-quality moulds and precision tools. In maintenance these replace the labour-intensive and often ineffective manual cleaning. The ultrasonic cleaning process can be used for all metal moulds, in particular tools for injection moulding, extrusion, rubber processing as well as aluminium and gravity die casting. A typical structure consists of three stages: 1. cleaning, 2. rinsing and 3. passivating. The usable dimensions are matched to common mould sizes. The workpieces to be washed are placed in the tank either with the aid of a washing basket or with a lifting beam. Our ErgoStation is recommended for manual rinsing, drying and post-treatment. The working area is completely enclosed, brightly illuminated and ventilated. Operation is safe and simple, as the moulded parts are loaded laterally through a sliding door and held by a lifting device during treatment.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

The WIWOX® VERSA GENIUS+ ultrasonic cleaning system enables individual, demand-oriented mould and parts cleaning. The modular design allows adaptation to almost all process requirements. Later expansion or automation is possible at any time. WIWOX® VERSA GENIUS+ ultrasonic cleaning systems consist of washing, jet, rinsing and drying modules as well as the corresponding accessories. The spectrum ranges from individually operated cleaning basins to fully automated, multi-stage cleaning lines. WIWOX® VERSA GENIUS+ sets new standards in modern plant design. Well thought-out details in the area of guiding the cleaning medium, agitation and process control ensure a flexible and energy-efficient process sequence that meets the requirements. You can convince yourself of the economic efficiency of the system by extensive cleaning tests in our test laboratory. The bath care accessories also play an important role in the cleaning result, the uniform process flow and the operating costs.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

The WIWOX® USm Ultrasonic cleaning tanks enable individual, demand-oriented surface treatment in a single or multi-stage process. The modular design allows adaptation to almost all requirements and subsequent expansion or automation is possible at any time. Aqueous cleaning at temperatures between 60° and 80° C ensures absolute degreasing and particle removal. Organic or inorganic residues such as polishing paste, paint, plastic, release agents, oil carbon or lime can be easily removed by using the right cleaner. The workpieces are cleaned within a few minutes. The cleaning result is always perfect and reproducible. The subsequent rinsing process is followed by stain-free post-cleaning or preservation. The WIWOX® ultrasonic cleaning process can be used for all steel moulds as well as brass and copper parts. Especially tools for injection moulding, extrusion, rubber processing, aluminium die casting and gravity die casting.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® PYRO paint stripping and decoating oven for particularly large and heavy batches. Particularly powerful furnace technology for the highest demands. With state-of-the-art IPC control and industrial burner technology. This furnace series enables clean, reproducible process parameters as well as state-of-the-art exhaust gas treatment.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Thermal cleaning in the WIWOX® IGS thermal system at up to 500° C removes all organic residues, even from fine bores. Depending on the melting and decomposition point of the residues, they are either melted or pyrolysed. The resulting exhaust air during the carbonization phase is burned in the afterburner chamber at over 850° C. Cleaning in the pyrolysis process requires subsequent post-cleaning. Inorganic components, oxidation residues, corrosion, etc. remain on the tool surface and must be removed. The ultrasonic process with acidic or alkaline cleaning media or the blasting process with organic and mineral abrasives are suitable for this purpose.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® Spintec top loader spray chamber washing systems are the solution for fast parts cleaning in maintenance! The parts to be cleaned are placed in the washing basket of the system from above. During the washing process, cleaning fluid is sprayed onto the parts from below, above and from the sides. The basket rotates inside the machine, resulting in an even washing result. The detergent reservoir is located in the bottom of the machine and is also equipped with a heater.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® VIVERK are single and multi-stage spray chamber cleaning systems for aqueous cleaning, pretreatment and degreasing of tools and parts. Loading takes place via an extendable platform, which can be loaded at an ergonomic working height. The workpieces are mechanically cleaned by means of pump pressure in the spray chamber process. The temperature-controlled washing liquid is sprayed onto the workpiece via a spray frame.The washing plant is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DP-EU pressure blasting cabinets clean and process tools and parts in just a few seconds. Fine blasting granulates are shot onto the surface by means of compressed air and remove dirt and corrosion. The blasting nozzle is manually guided during the processing of individual parts. Process automation is also possible. For this purpose, the workpiece or the blasting nozzle is moved by motor. The pressure blasting process is suitable for the removal of all solid, exposed residues and layers, especially on metallic surfaces of production tools and high-quality machine parts. Deburring and finishing of surfaces is also possible. In extensive tests with your tools you can convince yourself of the economic efficiency of our system. We will provide you with a test facility for this purpose after consultation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® DP-BB blast cabinets with combined blasting and blow-off function (Blast´n´blow®) and ex-protection accord. to 1999/92/EC for paint stripping and surface decoating in seconds. Fine organic blasting media get shot onto the workpiece by compressed air, whereby even stubborn thick layers are loosened in shortest time by the effect of the soft, but sharp-edged granulates. Even sensitive tool surfaces get not damaged. The blasting process is suitable for the removal of all solid, exposed residues, especially on metallic surfaces of production tools and high-quality machine parts. Blasting granulate and blasting pressure are adapted to the respective application. With the pressure blasting process you can clean extruder and injection moulding screws, blowing heads, moulds and profile tools much faster and more gently than with conventional cleaning methods. In extensive tests with your own workpieces you can convince yourself of the economic efficiency of our system.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® 410 is a liquid, alkaline mould cleaning agent for the removal of burnt rubber and plastic residues from metallic surfaces. It is also used as a paint stripper. WIWOX® 410 is used undiluted for immersion cleaning of metal moulds. The construction material for the tank can be sheet steel or stainless steel. The tank size depends on the moulds to be cleaned. The pool can be heated from the outside or inside by a heating coil. The processing temperature is generally approx. 80° C. The processing time depends on the degree of soiling and the type of soiling between 10 – 30 minutes.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® 340 is a weakly alkaline cleaning agent for grease, oil and oil carbon soiling. Very suitable for pre-cleaning or basic cleaning of soiled steel, cast iron and non-ferrous metal or plastic parts in an ultrasonic bath or in a spray cleaning system. After cleaning and without water rinsing, the parts are temporarily protected against corrosion. The final drying can be accelerated by blowing off with compressed air, a warm air flow or treatment in a drying cabinet. WIWOX® 340 can be used in a concentration of 5 – 7 %. Dilution with water depends on the degree of contamination and the intended exposure time. The bath should have a temperature of approx. 60° C. The bath should be kept at a constant temperature. In the field of precision mechanics, longer exposure times are possible depending on the degree of contamination.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® 250 is a very alkaline cleaning concentrate for organic (oil, coal, grease etc.) and inorganic (magnesium, lime etc.) residues on tools and moulds. It can be rinsed off residue-free without a film on the surface. The concentration depends on the working conditions, the degreasing time, the degree of soiling, etc. (between 5 – 30 %). Regular replenishment by checking the bath can prolong its service life. In contrast to powder concentrates, lthe iquid formulation allows convenient use without danger of exothermic reaction in the plant.

Request for a quote

WOMA GMBH

Germany

The highpressure pumps of the Z series deliver operating pressures up to 1,500 bar. With a high number of pressure and nominal flow rate combinations, the pumps are preferably used in industrial cleaning, paint stripping and also in descaling.For pumps with an operating pressure of more than 1,000 bar, hard metal plungers are used, which are particularly stable in order to guarantee a long service life and thus low maintenance costs.

Request for a quote

KAMAT GMBH & CO. KG

Germany

High-pressure cleaning and surface preparation with water requires precise management of the water jet. This precise management is necessary to ensure that the required result (e.g. surface finish) is achieved within a reasonable time. The method must be safe and fatigue free. With this in mind, we offer a specially designed and manufactured range of high pressure guns with electrical or mechanical control. The exceptional ergonomics of these tools have been achieved through innovative detail solutions: For example, our high-pressure guns are equipped with a special swivel handle that transmits any torque to the wrist. In addition, the hose connection can be swivelled in all directions, allowing optimum hose routing for all working situations. Our range of high pressure guns is complemented by various versions of foot valves, rotating gun lances, rotating nozzles and other accessories for a wide variety of applications, such as pipe cleaning.

Request for a quote

KAMAT GMBH & CO. KG

Germany

The KamJet is our solution for trouble-free extreme high pressure blasting on a mobile platform. The trailer mounted high pressure unit is powered by a 175kW Volvo diesel engine and produces pressures up to 3,000 bar for up to eight hours on a full tank of fuel. The KamJet mobile high-pressure unit with advanced control unit, optionally suitable for powering the Gekko system. Only high quality parts used - Our KamJet is a complete solution and comes mounted on a twin axle trailer that can travel at speeds of up to 100km/h. All parts and pipework on our units are made from stainless steel. Most importantly, it is equipped with a state of the art control system with touch screen or remote control that fully automatically controls the output pressure and speed. This makes it easy for the user to operate the machine and ensures uninterrupted operation. The KamJet can also be used with two users.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Performance in a small space Our compact K100-3 high-pressure three-plunger pump boasts impressive performance data: With only 15 kW of input power, it delivers a pressure of 2000 bar, making it one of the most powerful pumps in its size class. The K100-3 triplex plunger pump really comes into its own when it comes to water jetting for industrial high-pressure cleaning.

Request for a quote

KAMAT GMBH & CO. KG

Germany

With 110 kW, the K11000-3G high-pressure pump is a powerful plunger pump that is mostly used in intermittent operation. The reason for this is that this KAMAT high pressure pump has splash lubrication and not oil pressure lubrication. This makes the pump more suitable for intermittent operation, but it is extremely robust and can therefore be used in continuous operation even at 110 kW. Classic applications for this pump are industrial cleaning, blasting and process engineering. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Splash lubricated gearbox - Standard gear ratios i = 3,00 - 3,14 - 3,39 - 3,76 - 4,13 - 4,50 - 4,93 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils etc. on request, oils etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's K4500-3 three-plunger high-pressure pump is a powerful pump that is ideal for a wide range of industrial cleaning applications, water steel cutting, pressure testing, surface removal and machining. Modularity for customisation, also as a process pump With an output of 45 kW, the K4500-3 is the entry-level model in the proven KAMAT modular system. The modular design not only allows the use of different pump heads, but also adaptation to different operating pressures and pumped media. As a process pump, it can even handle fluids with viscosities up to 2000 mPas. SPECIAL FEATURES - Flow rate data at 100% volumetric efficiency - and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod force - Gearbox with splash lubrication - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Versatile, turnkey diesel high-pressure pumping units Special applications require customised high-pressure systems, which KAMAT can provide from the initial project idea through to turnkey installation, with 100% of the manufacture taking place in-house. Depending on the application, our customers can choose from a range of drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation. However, the units are ready for use on the base frame on which they are delivered. KAMAT diesel-powered units are traditionally used in industrial cleaning and pressure testing, mining and water hydraulics, but special solutions for special fluids or to meet explosion protection requirements are also part of the KAMAT range. It makes no difference whether the customer requires a mobile or stationary unit.

Request for a quote

KAMAT GMBH & CO. KG

Germany

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quoteResults for

Cleaning- industrial - Import exportNumber of results

44 ProductsCompany type

Category

- Sandblasting equipment (13)

- Cleaning machines, industrial (6)

- Pumps (5)

- Cleaning, industrial (4)

- Cleaning and maintenance products, industrial (3)

- Threads and yarns, artificial and synthetic (3)

- Precious and semiprecious stones and pearls (3)

- Cleaning and maintenance - equipment and supplies (1)

- Adjustment - machine tools (1)

- Electric and electronic components - machines for manufacturing (1)

- Industrial cabling (1)

- Medical fabrics (1)

- Piston pumps (1)

- Pumps, hydraulic (1)