- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shearing machine tools

Results for

Shearing machine tools - Import export

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 28 x 2 mm for stainless steel tubes Shortest separation length: — 25 mm (without pull apart) — 55 mm (with pull apart) Separation efficiency: up to 2,000 pcs per hour

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The linear manipulation system is perfectly suited for detaching complex structures, such as windows, manholes, cut-thoughs and circular sections. With its high flexibility, it can easily adapt to conditions on-site. The simple assembly operation is performed by means of tensioning belts. The system’s adaptation to the internal diameter is possible.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The mini MACE is suited for, for example, the cutting and opening of pipe bombs, hand grenades or potentially hazardous objects such as unconventional explosive devices in the form of fire extinguishers and cases. mini MACE combines an abrasive mixing unit and a high-pressure pump in a single casing. The working pressure of the unit, which is driven by an internal combustion engine, is 6525 PSI (450 bar). The mini MACE was developed as a mobile penetration and cutting tool. An autarkic complete system equipped with internal combustion engine, abrasive mixing unit (AMU) and high pressure pump for accessing and deactivating IEDD (Improvised Explosive Device Disposal). It could be also used in the industrial sector for e.g. opening tanks.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

Mobile water jet cutting unit particularly suited for Defusing large-caliber fund munitions EOD (Explosive Ordnance Disposal) & IEDD (Improvised Explosive Device Disposal). Environmental exposure over the time has chemical and/or physical effects on ammunition & often leads to a critical in-situ situation of the UXO. Conventional Render Safe Procedure (RSP) is very often not feasible without contacting or shifting the UXO and therefore is considered as not secure. In such situations repeatedly it came to severe accidents with death tolls. Hence safety of transport to carry-off for final removal is also not given.Therefore in such cases blasting the UXO is so far used as a final RSP causing partly heavy collateral damages. This unit allows to remove or deactivate the fuse remotely, risk-free & safe by using the WAS Technology & specially designed manipulation systems. The deployment of this technology around the globe has become state of the art today and is an accepted RSP world-wide

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

Facing new manufacturing challenges? Want to be quicker and more precise than your competitors? Then you need ConSus. The ConSus system is an Abrasive Mixing Unit (AMU) in which abrasive is added continuously to the pressurized water flow with the worldwide patented lock method. High capacity and low pressure have been unachievable in water jet cutting until now. That’s exactly what the Water Abrasive Suspension (WAS) cutting method from ANT delivers. Tests prove: The ANT suspension jet cuts two to three times faster than conventional water jet cutting methods and at less than half the pressure. The reason for this is the composition of the water jet - a suspension made of water and an abrasive, which is pressurised without air before being squeezed out of the nozzle. The omission of air allows the jet to cut much more efficiently. ConSus combines all of these benefits in a single unit, which can be integrated into any existing water jet cutting system.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The DW292 is specifically designed for cutting monocrystalline silicon ingots up to 300mm diameter into high quality wafers for the semiconductor industry. The newly developed DW292-300 can be operated with slurry wire, as well as with diamond wire, and has sophisticated features for optimizing warp and ripple. The longer wire field, as well as the higher wire speed and acceleration, enable a higher throughput per machine and year. The use of extremely thin wire is possible thanks to smaller inertia of moving parts, fewer deflection rollers and shorter wire distance. The DW292-300 is highly resistant to temperature fluctuations and vibrations due to its compact and robust machine frame made of mineral casting. Thanks to higher process automation and the new intuitive HMI with dialog-based production wizard, operation is safer, easier and faster.

Request for a quote

FLOW EUROPE GMBH

Germany

The Mach 3 series offers you the world’s most reliable ultrahigh-pressure pump, intelligent process monitoring, and an array of unparalleled options all integrated into the most powerful waterjet control available. This system configuration incorporates a design that combines the motion control, pump and high-pressure components into one compact machine. It consumes minimal floor space, provides excellent operator access, and is configured for easy material loading and unloading.

Request for a quote

GSW SCHWABE AG

Germany

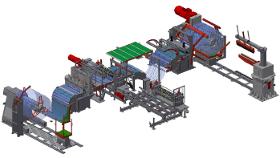

Cut-To-Length Lines are core competence at GSW. They belong to the family of Cutting Lines and are designed to process diverse materials out of steel, non-ferrous metals or aluminum and precisely cut a coil into sections of equal length (which is where the name comes from). Starting with narrow slit strip and finishing somewhere beyond 2000mm width – our Cut-To-Length Lines always know how to shine in this process.

Request for a quote

GSW SCHWABE AG

Germany

Also Slitting Lines do of course belong to the family of Cutting Lines. They are suitable especially for such customers who have to control a large portfolio of coil widths within their production. And if you build quality products you need quality even in your primary material. Finding it requires a good Steel Service Center but can be costly and unavailable at time of need. So why not cut your own coils? Our Slitting Lines are optimized for smaller batches and provide flexibility supporting your deadlines.

Request for a quoteResults for

Shearing machine tools - Import exportNumber of results

10 ProductsCountries

Company type