- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stamp die-cutting

Results for

Stamp die-cutting - Import export

PIERON GMBH

Germany

Dimensions Wire diameter: 0,3 – 4,5 mm spring-hardened Wire diameter: 0,3 – 7,0 mm soft Part length: customer specific after consultation Profiles other than round wire after consultation Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels Additional coatings available after consultation Meeting the closest tolerances Specialities Partial machining Stamping Thread cutting or rolling Fully automated mating with other parts Mounting and component manufacturing Processing of painted wires Rapid prototyping

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Laser cutting parts and bending parts: Your special production in good hands. As part of the Schulz Group, Schulz Stanztechnik can also offer you – as a service and in addition to the stamping program – special laser cut parts in various materials and thicknesses. In accordance with your drawings, you will receive a meaningful offer from us within three working days, and your laser parts within ten working days of your order. Manufacture of 2D and 3D laser parts made of the most diverse of materials as well as angles in accordance with your drawings and specifications.

Request for a quote

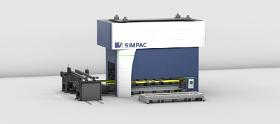

SIMPAC EUROPE GMBH

Germany

Compact and modular presses for a wide range of medium sized parts. Flexible installation options as a single press in progressive or transfer mode or as fully automated press line. Overview: ● Pressing capacity: 3,000 - 10,000 kN ● Component size: medium ● Slide kinematics: crank ● Applications: stamping, cutting, forming, bending, embossing Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 3,000 - 10,000 kN ● Part size: small to medium ● Slide kinematics: servo (freely programmable) ● Application: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes through the use of torque motors that provide high torque even at low speeds ● Maximum production flexibility due to freely programmable slide movement, slide velocity and stroke length ● Significantly higher output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 8,000 - 30,000 kN ● Part size: medium to large ● Slide kinematics: servo (freely programmable) ● Applications: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes thanks to the use of torque motors that deliver high torque even at low speeds ● Maximum production flexibility through free programmability of slide movement, (forming) speed and stroke lenths ● Significantly more output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

C-frame presses are flexible solutions for manual work as well as for automated production processes. The CS is the all-rounder among the C-frame presses, while the ECS is ideal for punching and cutting operations with a higher degree of automation. Overview: ● Press capacity: 350-3,000 kN ● Part size: small ● Slide kincematics: crank ● Application: cutting, stamping, bending, embossing Description and benefits: ● Compact design, no foundation work required, good accessibility for maintenance ● Solid, low-stress annealed press body in monobloc design with minimal frame deflection ● Durable, wear-resistant and very quiet hydraulic clutch ● Casting slide with vibration dampening properties (ECS series) ● 4-fold slide guiding for a high tilting rigidity ● Hydraulic overload protection ● Production time as of 12 weeks

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 062 Cutting, stamping and bending device for radial components Description The Streckfuss device Type C 062 is designed to process loose components with radial leads. Cutting and bending of the leads is done in one step including integrated strength member to eliminate axial strength uppon the component case. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 034/Mil Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height. In the device can be adjusted via adjustment screws C 034/Mil both cutting length and height and the components are then processed. The setting is displayed on the relevant scale of the device. The component is manually inserted between the tools. Those are actuated by a pneumatic foot switch. The changeover for different cutting and grid dimensions happens in less than a minute. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 034/S Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height. In the device C 034/S can be set via adjustment screws both cutting length and height and the components are then processed. The setting is displayed on the relevant scale of the device. The component is manually inserted between the tools. Those are actuated by a pneumatic foot switch. The changeover for different cutting and grid dimensions happens in less than a minute. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 042 Cutting, stamping and bending device for axial components Description The Streckfuss Device Type C 042 is designed to cut, stamp and bend the leads of axial components. By the use of interchangeable tool sets a variety of form configurations can be achieved with this device. The change can be done easy and secured in less than two minutes. The settings will be displayed on the scale of the device. The embossing for the leads are tooling- specific. This tools are produced to meet customer requirements. The components are hand fed into the tooling. The component body has to be centered between the bending anvils. After the Foot pedal is depressed, the component leads are clamped on both sides. The leads are then cut to length and depending on the form shape the required lead features are put in the leads at this time. After that, the leads are bend to the 90° configuration. The processed component is then rejected by the front of the device. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 042/S Cutting, stamping and bending device for axial components Description The Streckfuss Device Type C 042 is designed to cut, stamp and bend the leads of axial components. By the use of interchangeable tool sets a variety of form configurations can be achieved with this device. The change can be done easy and secured in less than two minutes. The settings will be displayed on the scale of the device. The embossing for the leads are tooling- specific. This tools are produced to meet customer requirements. The components are hand fed into the tooling. The component body has to be centered between the bending anvils. After the Foot pedal is depressed, the component leads are clamped on both sides. The leads are then cut to length and depending on the form shape the required lead features are put in the leads at this time. After that, the leads are bend to the 90° configuration. The processed component is then rejected by the front of the device. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043 Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043 is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/B Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - if necessary - marked. This axial taped components are processed in high- components. The machine type C 043 / B can be adjusted using the adjustment spindles cutting length and the embossing position. The setting is displayed on the relevant scale of the device. Optionally can be monitored through a digital display setting. The embossing tool is specifically for connecting pins and is manufactured according to customer requirement. The machine can be upgraded for the various tools. The taped components are fed into the machine and processed automatically. The transport speed is infinitely variable. The tool change for other forms of bending takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/BS Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - are marked - if necessary. This axial taped components are processed in high- components. The machine type C 043/BS can be adjusted using the adjustment spindles cutting length and the embossing position. The setting is displayed on the relevant scale of the device. Optionally can be monitored through a digital display setting. The embossing tool is specifically for connecting pins and is manufactured according to customer requirement. The machine can be upgraded for the various tools. The taped components are fed into the machine and processed automatically. The transport speed is infinitely variable. The tool change for other forms of bending takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/E Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043/E is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/ES Cutting, stamping and bending device for axial components Description To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Cutting length and pitch are fully adjustable. The stamping result for the leads depends on the used tool. Leadforming ist tool specific and can be manufactured to meet customer requirements. The difference to the types C 043 and C 043 E is the integrated Pneumatic which makes the rearrangement of the Bending- and Formingtools possible. This means, that the tools can be approached to the components. Espacially bendings with Flush- Mount- bead can be done. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 044 Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 044 is designed, to cut and form the leads of axial components for vertical mounting. A variety of form shapes are avalaible through the use of interchangeable die sets. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length and formed to required raster. The set up adjustments are quite simple and secured to provide accurate forming of every compöonent lead. Components

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 063 Cutting, stamping and bending device for radial components Description The device processes power transistors and diodes to the types of housing TO 92, TO 18, TO 126, TO 127 and TO 220 with a maximum of three radially running connections. However, other components can be processed (for example, LED). The cutting and bending of the connecting wires is carried out in one step and of course including cable strain relief in order to avoid axial forces on the component housing. When a component which is to be bent, embossed and cut, two processing stations are necessary. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 067 Cutting, stamping and bending device for radial components Description The Streckfuss machine Type C 067 is designed to process power transistors of types TO 18, TO 92, TO 126, TO 127 and TO 220 with 3 or more radial leads. Also different components (e.g. LED's) can be processed, which fit into the supply- shaft of the machine. The operation of the machine is restricted on filling up the exchangeable feed magazine with components to be processed. Optionally the machine can be equipped with a round- conveyor, to supply loose components automatically to the machine for processing. The tools are equipped with strain relief- valves to eliminate stress to the component body, when the leads are bend and cut. Once formed and cut the component is stored in a collection bin, seperated from shavings. The tool- change for different forms takes less than 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 068 Cutting, stamping and bending device for radial components Description The Streckfuss machine Type C 068 is designed to process power transistors of types TO 18, TO 92, TO 126, TO 127 and TO 220 with 3 or more radial leads. Also different components (e.g. LED's) can be processed, which fit into the supply- shaft of the machine. The operation of the machine is restricted on filling up the exchangeable feed magazine with components to be processed. After the processing action the components are then desposited into a second tube for collection. The tools are equipped with strain relief- valves to eliminate stress to the component body, when the leads are bend and cut. Once formed and cut the component is stored in a collection bin, seperated from shavings. The tool- change for different forms takes only about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 069 Cutting, stamping and bending device for radial components The Cutting and Forming Machine for horizontal & vertical Mounting and tube to tube feeding. The cutting and forming machine Type C 069 is designed to cut and form components with 3 up to 23 leads for vertical or horizontal mounting. The feed magazines and die sets are modular in design to allow quick set up changes. All cutting and forming parameters are manufactured to customer specification. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 069/G Cutting, stamping and bending device for radial components Description To eliminate belt- tolerances the Streckfuss machine Type C 069 G was developed with an integrated touch- facility. With this all usual in the trade component- belts which meet the IEC- Norm can effortless be processed. The component is formed and cut with a maximum tolerance of ± 0,1 mm. The supply of components is exclusively done by reel. For this the machine has a combined location for reel and amo- pack. To save set- up time all necessary toolkits for specific formings are mounted in one unit. These toolkits can be inserted or exchanged within a very short time. When inserting a toolkit the driving- mechanism automatically will be locked. The machine is prepared to keep 2 processing- units. One unit performs upward formings and the other performs downward formings. After the components have been formed and cut they are ejected into a bin for collection. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 092 Cutting, stamping and bending device for radial components Description The Streckfuss model C 092 has been developed to process taped components with holepitches of 12.7 mm and 15 mm with one machine. To eliminate any kind of inconsistencies due to variances in taping, this machine is fitted with a probing- unit that will verify the cut length. The machine was developed with two processing units for multiple die sets. The die inserts can be exchanged very quickly. Because of the dual processing- units a wide range of bending and stamping forms can be processed. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 093 Cutting, stamping and bending device for radial components Description The C O93 was designed to produce a "J" bend to one lead of a component that has polarity. CO93 incorporates a touch tool that ensures a specific lead length ± 0.1 mm even if the components are not taped to an exact tolerance. Optionally, the CO93 offers a C Tester that can test the components for correct polarity prior to the forming station and remove them if they fail. Because the CO93 only accepts components on tape, either reeled or ammo pack formats are acceptable. Also because of its flexibility, the CO93 allows the processing of components taped on 12.7 mm and 15 mm spacing by using easy- to- change tape guides and tools. Components

Request for a quoteResults for

Stamp die-cutting - Import exportNumber of results

25 ProductsCountries