- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stamp die-cutting

Results for

Stamp die-cutting - Import export

METAL IN LTD

Bulgaria

The modern equipment with CNC machines, which we possess allow us to work sheet iron with thickness till 18 mm and dimensions 1500x3000 mm. These products are with high quality, precise manufacturing and excellent external look. Thank to different machines and equipment (lazer cutting, stamp press, punching, shears, eccentric and hydraulic presses, machine shafts, bending machine for metal sheets straightening , spot welding, robotic MIG-MAG welding, WIG welding, powder coating. The company produce big variety of products as the more important are: Hydraulic reservoirs Metal boxes for electronics Wardrobes Cabinets for instruments Metal cabinets for coffee machines Front panels for professional speakers Fireplaces, burners and barbecues Gun safes and storage of documents Control panels for machines Doors and lids for machines and vacuum cleaners Equipment for stores Lamps for lighting Steps of excavators

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: 0,3 – 4,5 mm spring-hardened Wire diameter: 0,3 – 7,0 mm soft Part length: customer specific after consultation Profiles other than round wire after consultation Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels Additional coatings available after consultation Meeting the closest tolerances Specialities Partial machining Stamping Thread cutting or rolling Fully automated mating with other parts Mounting and component manufacturing Processing of painted wires Rapid prototyping

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Laser cutting parts and bending parts: Your special production in good hands. As part of the Schulz Group, Schulz Stanztechnik can also offer you – as a service and in addition to the stamping program – special laser cut parts in various materials and thicknesses. In accordance with your drawings, you will receive a meaningful offer from us within three working days, and your laser parts within ten working days of your order. Manufacture of 2D and 3D laser parts made of the most diverse of materials as well as angles in accordance with your drawings and specifications.

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

ALFAMAK is one of Turkey's leading gas spring manufacturers. Established in 2003, our company has been operating in the industry for 19 years and has gained a reputation for success. Gas spring is a new technology which comes instead of standard steel or polyurethane springs. A gas spring has a container of compressed Nitrogen gas with Piston Rod , Bush, Rod Rings, Valve etc. The Gas Springs are used in Cold Stamping industry to form, cut and fix the sheet metal inside the die. Many auxiliary materials are used for different purposes in the gas spring. Rod wiper, rod guide and rod seal are used on the inner surface of the bush. The purpose of the rod wiper is to prevent the oil and chips in the die from entering the gas spring. The rod guide is used to carry the load in case of axial force on the rod during use. The most important auxiliary material for sealing is rod/piston seal. It directly affects the performance of the product by keeping the gas in the gas spring.

Request for a quote

NLMK-EUROPE-PLATE

Belgium

Our large range of tool and engineering steels can easily combine toughness with conditioning, shaping and cutting. All these steels respond adequately to your needs of manufacturing hard and resistant tools and moulds. Whether you need them to withstand impact loading or to enable sharp cutting edges, they are made to ensure performance and durability. As a result of the right balance in alloys, our tool steels support high temperature without deformation. Their structure enhances their polishing properties. We can deliver quality tool steels as blocks (raw or machined) or as round bars (raw or peeled). Our extremely large range of thickness renders steels that meet your highest expectations. Applications : Plastic molding dies, die-casting die blocks, blanking and stamping dies, metal cutting tools, extrusion tools, hammers and sledges, etc.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Sheet metal stamping services more than 20 years,we are professional sheet metal fabricating factory in China Ningbo, we provide almost all kinds sheet metal forming services, such as die stamping,deep drawing,CNC bending,Laser Cutting... We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. Finished:Polishing,Brushed, Anodizing,hard anodizing,electroplating of chrome/zinc/nickel plated, tinning,copperize,Colour spray-painting, blackening, hot-dip galvanizing, tephlon plating, etc.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg is a professional machine parts manufacturer from China Ningbo, we are engaged in steel parts processing for 20 years, with a variety of processing equipment, to provide a variety of steel parts customized processing services. We provide a lof ot machining services, such as CNC turning, Automatic turning,CNC milling, Tool milling, dilling, grinding, wire cutting,colding forging, hot forging, die stamping, knurling,slot cutting,pressing,riveting.... In the past 20 years, we have processed all kinds of steel parts for domestic and foreign customers.such as tube couplings,steel shafts, pipe joint parts, hose connectors & transition connectors, copper machined tube, flange,bushing, knighthead, pedestal, customized screws,bolts, steel rods & steel pins... Our advantage is that according to the structure and use of parts, choose the lowest cost quality of the most reliable processing mode, improve the quality at the same time reduce the price of products.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

OEM Forging Auto Parts OEM Forging Auto Parts Manufacturer Process precision forging+ blasting+ cnc machining (https//www.frimaparts.com/precisionmachiningparts2/) Material Aluminum , Brass (https//www.frimaparts.com/brassforgingparts/) , carbon steel, stainless steel, iron Machining turning, milling, drilling, grinding, threading, CNC Finishing sand blasting, polishing, plating, acid treatment, anodizing, coating Design customized samples or drawings are accepted Weight range 0.1100KG Packaging paper carton + bubble bag Delivery time tooling/sample within 4 weeks, batch order within 4 weeks. Inspection all the products are strictly inspected by QC. We develop custom products for clients all over the world, such as 3D Robotics, Nvidia, Smart Systems and so on. We are experienced in many processes, such as stamping (deep drawing, bending), cutting (pipe cutting, profile cutting,

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

We almost have all the process in house, including machining(cnc milling, cnc turning, grinding), sheet metal fabrication(laser cutting, stamping, deep draw, bending, tube bending, welding). Please feel free to send us your inquiry.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

We almost have all the process in house, including machining(cnc milling,cnc turning, grinding), sheet metal fabrication(laser cutting, stamping, deep draw, bending, tube bending, welding). So Tower can make finished products, assembly parts like elevator parts in house, which can have better price and better control on quality also.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

We almost have all the process in house, including machining(cnc milling, cnc turning, grinding), sheet metal fabrication(laser cutting, stamping, deep draw, bending, tube bending, welding). So we are very suitable for the production of finished products, assembly parts in house, which can have better price and better control on quality also.

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Product Name: OEM 304/316 Stainless steel high-quality CNC machining parts, Factory custom precision steel CNC manufacturing metal steel parts our Materials machining capacity : Plastic ---ABS, PC, PMMA, PA(Nylon), ABS, Acrylic, PVC.etc. Metal---Aluminum, Copper, Brass, Bronze, Stainless Steel, Iron,etc. surface treatment: Painting, polishing, Silk-screen printing, (hard)Anodizing, Electronic plating, Sandblasting, Powder coating,Heat treatment,Passivation,ect. Available Format: PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE Tolerance Precision +/- 0.005 - 0.1mm / can also be customized. Precision Processing Drilling, Milling, CNC turning, Grinding, Bending, Stamping, Sheet metal, Laser engraving,Wire cutting, EDM & etc.

Request for a quote

FLEXIBLE MAGNET (CHINA) CO., LTD.

Hong Kong

Rubber Steel is a kind of Flexible Magnetic ReceptiveMaterials, magnets stick to it! Rubber Steel is made by iron powder and high quality thermoplastics. It is a kind of Magnetic Receptive Material, it is ideal for multiple applications at school, home, office or POP display etc. Magnetic Receptive – It is an ideal attraction base like steel for holding magnetic sheet, magnet strip or hard magnet, no restriction on pole alignment. Flexible – It is as flexible as rubber sheet, easy to lays flat, and can be applied to either flat or curved surface, won’t crease. Easy to use – It can be easily stamp, score, drill, hand – cut with knife or scissors without damaging its magnetic receptive properties. Easy to laminate – It is easy to laminate paper or PVC or self adhesive to the rubber steel to create more application as you need. Easy to apply – Adhesive backing attaches easily to metal, wood, plastic, or any smooth surfaces. Safer to us - Rubber Steel is lightweight and has no sharp edge, so it safer to use comparing to metal steel with sharp edges. Rustproof Durable, long last and easy to store. Rubber Steel available in a variety of options: Plain Brown, uncoated With adhesive backing Vinyl/PVC front, Vinyl/PVC available in different colors Write – on / wipe – off front Dimension: Rubber Steel is available in cut sheets and rolls Sheets can be die – cut or kiss – cut to required shapes and dimensions Standard dimension is as follows: Thickness width length Remark Range 0.3-1mm 1200mm max. No limitation Standard 0.5mm,0.6mm,0.75mm 620mm/1200mm 15M,30M,60M For rolls 500mm, 1000mm For cut sheets Customized dimensions are also available upon request Application: Magnetic Children’s game board Display boards Schedule boards Message boards Educational boards Magnetic dartboard Educational Aids Etc…

Request for a quote

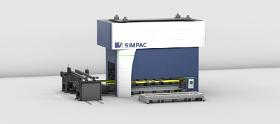

SIMPAC EUROPE GMBH

Germany

Compact and modular presses for a wide range of medium sized parts. Flexible installation options as a single press in progressive or transfer mode or as fully automated press line. Overview: ● Pressing capacity: 3,000 - 10,000 kN ● Component size: medium ● Slide kinematics: crank ● Applications: stamping, cutting, forming, bending, embossing Features and benefits: ● The compact design requires little floor space and no foundation at presses below 4,000 kN. ● The very solid, low-stress annealed press bodies are FEM-calculated and optimized by so-called “hot-spot analysis” in areas which are subject to higher loads. ● Motor, clutch/brake unit, lubrication system and control are of German origin and guarantee a long service life and maximum dynamics. ● The slide guiding system ensures a high level of tilting rigidity and reduces the cutting impact during the cut through when it comes to the processing of higher-strength materials.

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 3,000 - 10,000 kN ● Part size: small to medium ● Slide kinematics: servo (freely programmable) ● Application: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes through the use of torque motors that provide high torque even at low speeds ● Maximum production flexibility due to freely programmable slide movement, slide velocity and stroke length ● Significantly higher output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 8,000 - 30,000 kN ● Part size: medium to large ● Slide kinematics: servo (freely programmable) ● Applications: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes thanks to the use of torque motors that deliver high torque even at low speeds ● Maximum production flexibility through free programmability of slide movement, (forming) speed and stroke lenths ● Significantly more output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 062 Cutting, stamping and bending device for radial components Description The Streckfuss device Type C 062 is designed to process loose components with radial leads. Cutting and bending of the leads is done in one step including integrated strength member to eliminate axial strength uppon the component case. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 044/S Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - if necessary - marked . This axial taped components are processed in high- components. In the device 044 C / S to be bent, the components are manually inserted into the device and processed by triggering the pneumatic foot switch. The high- axial component can be provided either at one or at both terminal wires with a bead for preventing falling out of the printed circuit board according to the manual setting operation. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/E Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043/E is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 034/Mil Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height. In the device can be adjusted via adjustment screws C 034/Mil both cutting length and height and the components are then processed. The setting is displayed on the relevant scale of the device. The component is manually inserted between the tools. Those are actuated by a pneumatic foot switch. The changeover for different cutting and grid dimensions happens in less than a minute. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 067 Cutting, stamping and bending device for radial components Description The Streckfuss machine Type C 067 is designed to process power transistors of types TO 18, TO 92, TO 126, TO 127 and TO 220 with 3 or more radial leads. Also different components (e.g. LED's) can be processed, which fit into the supply- shaft of the machine. The operation of the machine is restricted on filling up the exchangeable feed magazine with components to be processed. Optionally the machine can be equipped with a round- conveyor, to supply loose components automatically to the machine for processing. The tools are equipped with strain relief- valves to eliminate stress to the component body, when the leads are bend and cut. Once formed and cut the component is stored in a collection bin, seperated from shavings. The tool- change for different forms takes less than 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 034/S Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height. In the device C 034/S can be set via adjustment screws both cutting length and height and the components are then processed. The setting is displayed on the relevant scale of the device. The component is manually inserted between the tools. Those are actuated by a pneumatic foot switch. The changeover for different cutting and grid dimensions happens in less than a minute. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 042 Cutting, stamping and bending device for axial components Description The Streckfuss Device Type C 042 is designed to cut, stamp and bend the leads of axial components. By the use of interchangeable tool sets a variety of form configurations can be achieved with this device. The change can be done easy and secured in less than two minutes. The settings will be displayed on the scale of the device. The embossing for the leads are tooling- specific. This tools are produced to meet customer requirements. The components are hand fed into the tooling. The component body has to be centered between the bending anvils. After the Foot pedal is depressed, the component leads are clamped on both sides. The leads are then cut to length and depending on the form shape the required lead features are put in the leads at this time. After that, the leads are bend to the 90° configuration. The processed component is then rejected by the front of the device. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 042/S Cutting, stamping and bending device for axial components Description The Streckfuss Device Type C 042 is designed to cut, stamp and bend the leads of axial components. By the use of interchangeable tool sets a variety of form configurations can be achieved with this device. The change can be done easy and secured in less than two minutes. The settings will be displayed on the scale of the device. The embossing for the leads are tooling- specific. This tools are produced to meet customer requirements. The components are hand fed into the tooling. The component body has to be centered between the bending anvils. After the Foot pedal is depressed, the component leads are clamped on both sides. The leads are then cut to length and depending on the form shape the required lead features are put in the leads at this time. After that, the leads are bend to the 90° configuration. The processed component is then rejected by the front of the device. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043 Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043 is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/B Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - if necessary - marked. This axial taped components are processed in high- components. The machine type C 043 / B can be adjusted using the adjustment spindles cutting length and the embossing position. The setting is displayed on the relevant scale of the device. Optionally can be monitored through a digital display setting. The embossing tool is specifically for connecting pins and is manufactured according to customer requirement. The machine can be upgraded for the various tools. The taped components are fed into the machine and processed automatically. The transport speed is infinitely variable. The tool change for other forms of bending takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/BS Cutting, stamping and bending device for axial components Description To facilitate the placement of short axial leaded components that must be cut before insertion into the circuit board to the appropriate length and bent to the required height and - are marked - if necessary. This axial taped components are processed in high- components. The machine type C 043/BS can be adjusted using the adjustment spindles cutting length and the embossing position. The setting is displayed on the relevant scale of the device. Optionally can be monitored through a digital display setting. The embossing tool is specifically for connecting pins and is manufactured according to customer requirement. The machine can be upgraded for the various tools. The taped components are fed into the machine and processed automatically. The transport speed is infinitely variable. The tool change for other forms of bending takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/ES Cutting, stamping and bending device for axial components Description To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Cutting length and pitch are fully adjustable. The stamping result for the leads depends on the used tool. Leadforming ist tool specific and can be manufactured to meet customer requirements. The difference to the types C 043 and C 043 E is the integrated Pneumatic which makes the rearrangement of the Bending- and Formingtools possible. This means, that the tools can be approached to the components. Espacially bendings with Flush- Mount- bead can be done. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 5 minutes. Components

Request for a quoteResults for

Stamp die-cutting - Import exportNumber of results

42 ProductsCountries

Category

- Sheet metals - stamping (7)

- Metal industrial presses (4)

- Foams, plastic (2)

- Lifts and platform elevators, car (2)

- Machine tools, metal machining - parts and accessories (2)

- Foams, rubber (1)

- Gas - production plants (1)

- Laser - cutting and welding machines (1)

- Mechanical engineering - custom work (1)

- Metalworking hand tools, non-power (1)

- SMALL METAL PARTS (1)

- Sheets and bands - ferrous metal (1)

- Stamping - machine tools (1)

- Stamps and seals (1)

- Steel & Metals (1)

- Wire springs (1)