- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat exchanger tubing

Results for

Heat exchanger tubing - Import export

ANTHERMO GMBH

Germany

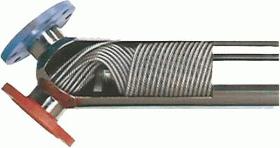

Tubes wound into a spiral shape Coaxial heat exchangers consist of two or more pipe coils, which are routed into one another and wound up in a spiral shape. The primary medium runs in countercurrent to the secondary medium. Fast temperature exchange This countercurrent design achieves a very rapid temperature transition with high efficiency between the liquids. Due to the spiral shape, the rapid temperature exchange between the liquids is achieved in a very small space. No cleaning or maintenance required Another advantage is the encapsulation of both liquids from environmental influences. There is practically no cleaning or maintenance effort due to pollution from the environment. The coaxial heat exchanger also does not require any seals that require maintenance. Condenser or evaporator function Coaxial heat exchangers can be used for both condenser and evaporator functions.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Heat exchangers – used to cool, heat or reheat fluids, gases and air – are an area that Superior Tube specializes in. We offer a range of products specifically meeting the demands of companies fabricating shell and tube heat exchangers. Our heat exchanger tubes are used in a wide range of industries such as chemical processing, hydrocarbon processing and oil refining, alternative energy, nuclear power generation and aerospace. The stainless steel and nickel alloys we manufacture are high strength, corrosive resistant alloys that maintain optimum performance in extreme conditions. Superior Tube heat exchanger products can be purchased as seamless, welded or welded and drawn tubes in a multitude of sizes ranging from 0.010” OD to 1.500” OD with wall thickness as light as .003” Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Fine Tubes is a leading supplier of high-quality cooling and heat exchanger tubing across a range of industries. Nuclear Cooling Tubes Our high-quality seamless cooling tubes are trusted by the world’s major nuclear reactor suppliers for range of technologies. Typical alloys include stainless steel alloys 690, 304, and 825. Nuclear island applications include: Passive residual heat removal heat exchangers regenerative Non-regenerative heat exchangers Turbine island nuclear applications include condenser tubes, stator bars for water and hydrogen cooling in generators, and cryogenic heat exchanger tubes. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Fine Tubes leads the manufacture of precision tubes required in the fabrication of shell and tube heat exchangers. Our heat exchanger tubes are used for the cooling, heating, or re-heating of fluids, gases, or air in a diverse range of industries. Alloys Fine Tubes heat exchanger products are produced as seamless, welded or welded redrawn tubes in the following materials nickel alloys, stainless steels, duplex, super duplex. Please note that we have a minimum order value of £10,000.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

We design and manufacture products based on the project sent by our customers or according to customer requirements. Calculations, designs and projections according to customer demand and in accordance with ASME Code Section VIII Div 1 and 2 (American Society Mechanical Engineers), API 661, API 650 (American Petroleum Institute), TEMA (Tubular Exchanger Manufacturers Association), AD-MERKBLAATTER, CODAT, DIN, EN 13445, PED 2014/68 / AB and TSE. The most common processes in the Oil & Gas, Petrochemical & Chemical, Food & Beverages and Heavy & Light Industry require a significant number of equipment to exchange heat or to storage different fluids or components. The fluid can be either liquid or gas, and one of each flows into the tube and the other flow out of the tube is used to boil, condense or cooling the fluid.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Double tube heat exchangers (also known tube-in-tube) are designed whereby one tube is concentrically positioned within a larger tube. The double tube composition allows for unrestricted flow of product, making it the ideal heat exchanger for viscous products. The product flows through the inner tube and the service fluid flows through the surrounding shell.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Recuperator systems are heat exchangers that produce hot air by utilizing the energy of high-temperature waste flue gas generated in furnace systems, boiler systems and various processes. Recuperators various heating needs of facilities such as combustion air preheating and ambient heating are met and energy consumption is minimized. Compared to economizers, they have larger surface area and dimensions at the same heat capacity. They can be manufactured as finned tube and straight tube. Recuperator heat exchangers can be made from numerous materials steel, stainless steel and other special materials.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

Heat transfer between a gaseous media and a liquid finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air, steam) and a liquid (for ex. water, seawater, oil) takes place in the air-/water heat exchangers. Very often air/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube radiators can also be used as air heater, air cooler or condenser To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. The great increase of the thermal efficiency when applying fin tubes allows a substantial reduction in size and costs of such cooling equipment. The surface of such tubes is substantially increased and consequently less tubes are required compared with exchangers with plain tubes.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-water heat exchangers for industrial use Three types of air-water heat exchangers Three different designs o air-water heat exchangers The Anthermo GmbH delivers three different designs of air-water heat exchangers: Finned tube heat exchangers Lamella heat exchangers Straight tube heat exchangers These heat exchangers are designed in a way, that inside the tube water or another liquid circulates. The air flows around outside the tubes or the fins/lamellas. The connection between the fins and the tube is used to enlarge the space for heat transfer between the liquid and the gas fluid. The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-water heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

There are two different construction types. It's possible to create a design using a little construction space using the customer's data. The Thermo-Fluid S is connected directly between the oven pipe (or the heating system) and the chimney. The operating temperatures are up to 300°C (standard). The Thermo-Fluid S is low maintance with low pressure drop in the flue gas. Depending on the application you can have energy savings up to 15 %. A bigger construction is the Thermo-Fluid M, which is optimised for utilisation of waste heat from process air, flue gas or exhaust air. An energy yield of up to 1600 kW is possible, whereupon the pressure drop in the process air is less than 1.5 mbar. The pressure drop in water circuit is less than 200 mbar. This Shell and Tube heat exchanger is low maintance using the small type of construction. The Thermo-Fluid M modular and the standard temperatures are up to 300°C too. Both Shell and Tube Heat Exchangers are low maintance. One-off or

Request for a quote

UNEX HEATEXCHANGER ENGINEERING GMBH

Austria

The UniCompact is a very versatile heat-exchanger, suitable for use in wide ranging applications, including liquid, gas and steam. The sealed units require no maintenance and the robust construction and variety of materials ensure a long service-life. The choice and design of the right UniCompact for your requirements will be calculated for you by an expert at UNEX. Thousands of these heat-exchangers have already been supplied and are reliably in use around the world. Depending on your needs, the UniCompact can also be delivered with fixtures, fittings, connections and insulation.

Request for a quote

UNEX HEATEXCHANGER ENGINEERING GMBH

Austria

UniTwist heat-exchangers are particularly suited to the demands of food, pharmaceutical and industries where absolute cleanliness is paramount. In extra demanding situations a UniScrape, self-cleaning version can also be supplied. Semi-fluids, pulps, liquids with particulate or sediment content and fibrous mass can be processed. The concentric tube system can be supplied in a variety of smooth, hard or dimpled finishes, depending on the process requirements. UniTwist can be designed to fit in confined and restrained areas, the ability to produce a coiled heat-exchanger is particularly appropriate for fitment around existing tanks. A variety of fixtures, fittings and connections are available depending on the requirements.

Request for a quote

UNEX HEATEXCHANGER ENGINEERING GMBH

Austria

For the condensation of refrigerants in commercial and industrial refrigeration systems. The condensers are suitable for outdoor installation and can be installed in residential and industrial areas according to the sound pressure levels. There is a selection of over 1,500 models with four different sound pressure levels and construction sizes, depending on the application. The condensers, available in stainless steel/aluminium, are suitable for refrigerants (Frigene) and ammonia (NH3), depending on application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KASAG SWISS AG

Switzerland

You state your requirements and send us the material properties. KASAG then configures the thermal and hydraulic calculations for the desired heat exchanger. The realization is implemented according to the available drawings or on the basis of a comprehensive engineering. KASAG offers all processes necessary for that, such as the orbital-welding process for manufacturing heat exchangers. With KASAG, you can be sustainably flexible.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of liquids Tube coil heat exchangers (so-called tube cooling coil heat exchangers) are generally used to control the temperature of liquids. This system can also be used to heat or cool liquids in a controlled manner. Due to their special shape, pipe coil heat exchangers are sometimes also called hairpin heat exchangers. Inexpensive applications The simple and solid structure enables it to be used in cost-effective applications. Coiled tube evaporator systems are ideally suited for brine and glycol applications. Classic variant Coiled tube evaporator systems are a classic and proven variant in the field of heat exchanger systems. Coiled tube heat exchangers are often used in ice storage systems or in the production of cold water units. In ice storage systems, coils can be used to achieve an even build-up of ice around the coils.

Request for a quote

EC PLAZA

South Korea

TRIS supplies tubes of various specifications and steel grades for petrochemical plant construction. TRIS has supplied not only straight tubes but also Seamless Coiled tube with longer length. The seamless coiled tubes have many benefits with reducing welding pointsand minimized the leakage points and helping to reduce the construction period in dramatically. In 2013, TRIS developed the Seamless Coil Tube. Now, TRIS can handle various steel grades such as 904L, C-22, Incoloy825, Super Duplex etc. of Coiled Tube and Straight Tube. The longer length of Nickel alloy coiled tube is usedfor chemical injection, hydraulic control, gas detect line etc. in Oil & Gas industry. In addition to the heat exchanger tubes of TRIS of chemical plant used in severe environmentsprovide the most efficient operation conditions by stable quality control and various Ni alloys.

Request for a quote

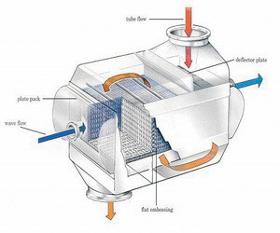

UNEX HEATEXCHANGER ENGINEERING GMBH

Austria

The UniWeld combines the advantages of conventional shell and tube heat-exchangers with spiral and plate heat-exchangers due to its design and construction. This mixed construction is based on the design of the heat-transfer channels, which are on one side in the tube design and on the other side in a plate heat-exchanger. UniWeld Hybrid exchangers utilise in this way the advantage of tubular heat-exchangers (high temperature, pressure resistant and solid construction) and plate heat-exchangers (high heat transfer, minimal space and low logarithmic temperature difference) in a compact system. Other advantage compared with gasketed plate heat-exchangers is the safe splitting of the 2 media at pressures up to 80 bar and between -200°C and +900°C.

Request for a quote

EVAPTON HEAT EXCHANGER

Turkey

EVA SERIES SHELL&TUBE EVAPORATORS RANGE FROM 20KW TO 1510 KW COOLING CAPACITY IN EVAPTON'S STANDARD CONDITIONS. THE REFRIGERANT SIDE CAN BE MANUFACTURED FROM 1 CIRCUIT TO 4 CIRCUITS. EVA SERIES EVAPORATORS CAN BE USED IN HCFC AND HFC REFRIGERANTS WITH MEDIUM TO HIGH SYSTEM PRESSURE (30-45 BAR). EVA SERIES EVAPORATORS CAN BE MANUFACTURED BOTH IN STANDARD CATALOGUE DIMENSIONS AND IN THE DIMENSIONS REQUESTED BY THE CUSTOMER. EACH EVAPORATOR MANUFACTURED IS CONTROLLED AND TRANSMITTED TO THE CUSTOMER BY MEANS OF UNILAB LICENCE PROGRAMME FOR CAPACITY AND PRESSURE DROPS.

Request for a quote

EVAPTON HEAT EXCHANGER

Turkey

IT IS THE MOST WIDELY USED HEAT EXCHANGER IN INDUSTRIAL FACILITIES SUCH AS IRON AND STEEL, PETROLEUM, PETROCHEMICAL, GAS, POWER PLANTS, FOOD, PHARMACEUTICALS, LEATHER, TEXTILES, AIR CONDITIONING, SHIPS AND MARITIME SECTORS THE HEAT EXCHANGERS USED IN THE INDUSTRIES CAN BE USED IN ALL SECTORS WHERE THERE IS A SECOND ALTERNATIVE ENERGY REQUIREMENT FROM AN ALTERNATIVE ENERGY WHILE ONE FLUID RUNS THROUGH THE TUBES, OTHER FLUID FLOWS OUTSIDE THE TUBES BUT INSIDE THE SHELL AS PARALLEL OR ACROSS THE TUBES. SO, HEAT IS TRANSFERRED OVER TUBE SURFACES. IT CAN BE PRODUCED AS COPPER TUBE, BAFON TUBE(CU-NI), STAINLESS STEEL AND STEEL.

Request for a quote

EID

France

or the service of installation technicians, eid exercises strict quality control on the copper, coils, bars, REFNET® refrigerant tubing. Here are a few explanations: THE TECHNICAL PROBLEM Technical performance of the air conditioning and refrigeration systems with the new refrigerant fluids (R410A, R32, etc.) is considerably reduced by the effect of the residual mineral oil used in the manufacture of ACR tubes ACR, used for heat exchangers and refrigerant tubing. THE SOLUTION Installing SUPERCLEAN tubes guarantees less residue inside the tubes. The internal residue ratio, defined as 0.1 mg/m, is only one sixtieth of that of conventional tubes. This means that there is no need for future cleaning of the exchangers and tubing, thus increasing the performance of the air conditioning and refrigeration systems. Our copper is manufactured using Grade A cathodes.

Request for a quote

INOXYDA SA

France

We manufacture channels, covers, floating heads and tubesheets in aluminium bronze (ASTM/ASME B148 C95800, C95400...). , delivered "as cast" , rough or fully machined according to customer specifications. Aluminium bronze is mainly used for applications using seawater and faced with sea water corrosion issues.

Request for a quote

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

A Heat Exchanger is a device built for efficient heat transfer from one medium to another, whether the media are separated by a solid wall so that they never mix, or the media are in direct contact.

Request for a quote

KELVION HOLDING GMBH

Germany

A Box Cooler is a vessel water cooling system. It comprises a U-tube bundle that is fitted in the sea chest on the side of a vessel, saving space in the engine room. The sea chest is equipped with inlet and outlet grids. Cooling sea water enters through the inlet grid and flows along the U-tube bundle to the outlet grid, thus cooling the water inside the tubes. The cooling effect is achieved by the forced circulation of sea water when the vessel is moving or by natural convection when it is stationary. Box coolers can be used for a wide variety of temperature-reducing duties on a vessel, from cooling the main engines, auxiliary engines and bow thrusters to air conditioning and hydraulic systems. Kelvion Box Coolers are ideal for small and medium sized vessels, including for example: tugboats, barges, fishing boats, carriers, dredgers, supply vessels, ferries, ice breakers, cargo freighters, tankers and reefers.

Request for a quote

KELVION HOLDING GMBH

Germany

Different applications require different designs for an optimal fit, so we provide Shell & Tube heat exchangers in single tube design with plain, low and high fin tubes and also with compact fin bundles. The plain tube design is most suitable if media have similar heat transfer properties, where the compact fin design means the best possible performance if there is a substantial difference in heat transfer rate, for example when exchanging heat between oil and water. The low and high fin single tube solution is between the previous two designs in order to further optimize on flow, pressure drop and velocities of media.

Request for a quote

KELVION HOLDING GMBH

Germany

Double tube safety heat exchangers play an important role in applications where preventing media mixing in the event of a leak is paramount. They are widely used and accepted as standard in the chemical industry, power, heavy and light industry, oil & gas, marine, transportation, refrigeration and food & beverage sectors. Kelvion has a long track record in developing ground-breaking technologies always aiming to reach the highest levels of safety, environmental protection and cost-efficient operation. Our expert engineers are fully trained to provide you with the best-in-class solutions tailored to your specific requirements. As industries face ever stricter regulations for safeguarding requirements of environment and water supply, double tube safety heat exchangers are the technology of choice.

Request for a quoteResults for

Heat exchanger tubing - Import exportNumber of results

98 ProductsCountries

Category

- Heat exchangers (76)

- Gas and oil - exploitation (10)

- Refrigeration plants and equipment, commercial and industrial (7)

- Oiling - machines and systems (6)

- Electric motors and parts (3)

- Pipes and tubes, stainless steel (2)

- Air conditioning equipment (1)

- Boilers, stainless steel (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Copper and copper alloys (1)

- Heat treatment furnaces (1)

- Industrial maintenance (1)

- Industrial piping (1)

- Laboratory equipment and instruments (1)

- Mechanical engineering - custom work (1)

- Nozzles - ferrous metal (1)

- Pipe and tube fittings - ferrous metal (1)

- Pneumatic system components (1)

- Radiators - fin-type (1)

- Seamless pipes and tubes - ferrous metal (1)