- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical belt

Results for

Mechanical belt - Import export

ROBINSON CO.

Turkey

Thanks to the belt-pulley mechanism driven by an electric motor, the rotational motion is transferred to the sieve shaft. The sieve weights, which are placed unbalanced, connected to the sieve shaft, make the sieve vibrate. The position of the screen weights can be adjusted around the screen shaft in order to change the vibration amplitude of the screen. The screen is hung on the ceiling of the place where it is located by means of composite rods in order to create the vibration comfortably. Thanks to this vibration movement, in specially designed sieve boxes, the incoming product is classified and sifted according to its grain size. The product to be screened is sent to the screening area through one or more inlet pipes. Various types of silk-covered cases allow separation in seven channels. This part is directed to the outlet by the channel. After the product is sifted, it is sent to the outlet pipe on the bottom plate. It also has sight pipes for product control and monitoring.

Request for a quote

ROBINSON CO.

Turkey

It is used for peeling the shells of wheat, barley, rye and similar grains and for cleaning dust, sand, small seeds, husks, insects and foreign matter stuck on these grains. The grain is cleaned and peeled by means of self-friction with an intense pressure, rubbing against steel metal anchors placed on the rotor, and rubbing against the knitted fabric of a special material that is rolled out cylindrically on the braided liner suitable for abrasion. The dusts are directed out of the pores of the shirt to the dust chamber and to the outlet through the bunker. Wheat, on the other hand, is taken out by directing it to the outlet in the jacket with the angle of the anchors. Application Fields In flour and semolina factories, Cleaning facilities of wheat, rye, barley, corn and similar grains, Used in grain storage silos. The machine is driven by a belt-pulley mechanism and can be used with any air duct or a tarar.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

mechanical belt connectors for use with most PVC, rubber and steel elevator belts, e.g. Supergrip belt connectors Easy to install system with 50 mm segment widths Four versions for up to 1,250 kN/m without limiting belt strength Max. temperature 80ºC, lock nut with nylon insert (standard) Type BC belt connector for steel mesh belts Four versions for up to 2,500 kN/m belt tensile force Maximum stability using high load bolts with self locking nuts Top quality construction in steel and extruded aluminium

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper PU molded timing belts (form belts), which are cast in special molds, are made of abrasion-resistant polyurethane and high-strength steel cords (or aramid cords). The cast PU timing belt is an exact replica of its mold. Consequently, high pitch accuracy along the entire length of the belt is realized. They are particularly well suited for smooth running and high speeds. By combining high-quality materials and this modern production method, the resulting timing belts exhibit supreme mechanical, chemical and physical properties. Mechanical properties: Low longitudinal tolerance Longitudinal stability, negligible elongation Form-fit, synchronous running Low noise High abrasion resistance Favorable performance-weight ratio Chemical properties: Good ageing resistance Operating temperature range from -30°C to +80°C Resistant to simple oils, greases and gasoline Applications All types of drives Office machines Textile machines Wood-processing machines

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper open-ended PU timing belts are made of abrasion-resistant polyurethane and high-strength steel cords or aramid cords and are available in open lengths. These timing belts are very suitable for synchronous conveying and positioning applications because they have very high flexibility and can be made with many different tooth shapes and materials; when combined with different tension cords, innumerable applications are possible. Keiper open-ended PU timing belts can be produced endless welded and by the meter in almost all lengths and widths. Based on this combination of high-quality materials and production methods, these belts exhibit outstanding mechanical, chemical and physical properties. Endless welded timing belts are available in any length. Welded PU timing belts primarily are used in conveying technology.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper profiles and cleats Many special, innovative tasks required in the material flow, such as pacing, separating or positioning, can be realized by adding profiles/cleats and entraining elements to the belts. Profiles and entraining elements are made of the same high-quality polyurethane as our timing belts, are mechanically processed as sheets or injection molded. They are available in different blends and degrees of hardness, with glass-fiber reinforcement and in a matching color. The profiles and entraining elements are homogeneously fastened to the belt by welding or glueing. In view of our production methods, the cleats can be formed into any shape.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The latest development in lifting platform technology is based on mechanical drive technology using belts. Hydraulic oil is not required. Due to a patented catch system, BELT-LINE meets the safety requirements laid down in DIN EN 1570. The combination of exemplary positioning accuracy, smooth running and long service life is the reason the BELT-LINE is an economical precision solution, and not only for sensitive areas. Exemplary smooth running BELT-LINE convinces with a low noise and harmonious movement sequence, paired with maximum lifting speed and positioning precision. Minimum maintenance time and costs without hydraulic oil In particular in sensitive areas, the robust BELT-LINE technology with its long operating life is the best possible solution. The low-wear components can be quickly replaced due to the modular design. Excellent load change behaviour In the design phase, particular emphasis was placed on developing an excellent load change behaviour. The resilient suspension behaviour is only surpassed by LAWECO push-chain lift platforms.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The innovative LAWECO CHAIN-LINE lifting platform technology unites all advantages of belts and spindles. Mechanically driven by a push-chain, this technology achieves maximum performances without the use of hydraulic oil. Due to a particularly harmonious motion sequence and the excellent load change behaviour in each lift position, the CHAIN-LINE is the preferred solution for designers who place an extremely high value on efficiency and precision for their area of responsibility. Unsurpassed precision LAWECO push-chain lifting platforms convince with a load behaviour and maximum positioning precision which were almost unachievable in the past. Unrestricted availability Almost maintenance free, the robust and low failure construction permits fast component replacement. Safety for the environment and employees The intelligent design does without hydraulic oil. Optional contact rails and bellows increase safety.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

It is similar to chain mechanisms in terms of its working principle, as it carries out motion transmission in a closed manner. In terms of materials, it is similar to belt-pulley mechanisms The conversion rate is fixed. The movement can be precisely synchronized as desired. Does not require lubrication. It gets very little hot during operation, It works noiselessly. It allows the use of very small diameter gears.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Bando V Belts are designed to handle heavy industrial applications and are constructed using high quality materials including rubber, polyurethane and other synthetic materials to ensure optimum performance, durability and reliability. Bando V Belt and pulley mechanisms are machine elements used to transfer power from one shaft to another shaft. They are flexible elastic machine elements called belts, which are wound on pulleys connected to two shafts.

Request for a quote

ERO JOINT .TANALS

France

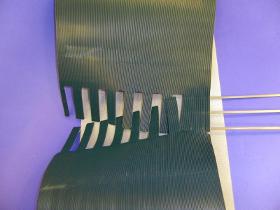

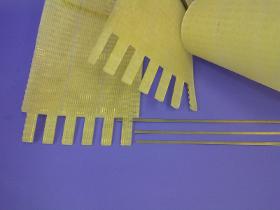

Exclusive Gates and Tanals The only power transmission belt with mechanical assembly The mechanical fastening system ERO Joint® - developed by Tanals - provide various possibilities to assemble belts on-site without having to disassemble pulleys or axes and to release the transmission. ERO Joint® and ERO joint® Ultimate are developed for and with Gates by Tanals. They offer unique solutions system for easy and fast repair of power transmission. The cutting shapes of the junction fingers have been engineered for maximum tensile strength and fatigue resistance of the Poly Chain® GT Carbon™ material. The power of Gates combined with the creativity of Tanals. Poly Chain® GT Carbon™ outstanding mechanical performance combined to patented innovative solution ERO Joint® Ultimate offer the only transmission belt with mechanical assembly whose performances equal those of all other endless belts on the market. A sustainable solution able to replace any rubber belt.

Request for a quote

ERO JOINT .TANALS

France

Exclusive Gates and Tanals The only power transmission belt with mechanical assembly The mechanical fastening system ERO Joint® - developed by Tanals - provide various possibilities to assemble belts on-site without having to disassemble pulleys or axes and to release the transmission. ERO Joint® and ERO joint® Ultimate are developed for and with Gates by Tanals. They offer unique solutions system for easy and fast repair of power transmission. The cutting shapes of the junction fingers have been engineered for maximum tensile strength and fatigue resistance of the Poly Chain® GT Carbon™ material. The power of Gates combined with the know-how of Tanals. Poly Chain® GT Carbon™ outstanding mechanical performance combined to ERO Joint® provide the only existing transmission belt with mechanical assembly. The only existing transmission belt with mechanical assembly, a unique solution on the market. Suitable for all HTD installations.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical joint system, you will save time and optimize your production downtime by reducing the repair time. The mechanical assembly of ERO Joint® round belts is substantially better compared to another mechanical joint system. There is no other mechanical joint system in round belts with traction cord. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® round belts are spliced in our production using a patented process and fitted with the length requested. Anyway using ERO Joint® round belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® round belts are easy to assemble. Alternatives Hollow round belt with fastening system Hollow round belt with connector are only used for very low mechanical resistance.

Request for a quote

ERO JOINT .TANALS

France

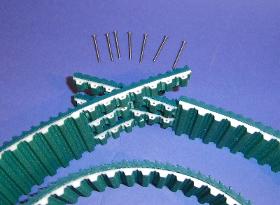

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. Mechanical splicing system ERO Joint® are also possible in conveyor belts with sealed tension members (like Gates PosiClean® and FlatClean FC12™) ->More about PosiClean® ERO Joint® belt The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

ERO JOINT .TANALS

France

The mechanical fastening system ERO Joint® is available on pitches T10, AT10, T20, AT20, 8M, 14M for all widths over 16mm with reinforcement Steel, Kevlar or Stainless steel. (The recommended minimum diameter for pulleys is 50mm). The ERO Joint® splice is compatible with all type of coatings (Supergrip, Linatex®, PU, Sylomer®, …) and all types of guiding. ADVANTAGES Advantages are a fast and easy installation and assembly. With the pin mechanical fastening system ERO Joint®, you will optimize your production downtime by reducing the repair time. The assembly can be realized by screwing or with a tool. This tool enables the pre-tension of belt and makes pins threading easier. ERO Joint ® Ultimate version In Ultimate version, the mechanical belt fastener ERO Joint® transmits more than 50% of the power of a Flexbelt (true endless belt): Between pulleys, there is always a ½ continuous tight side to assure the mechanical resistance and the rigidity of the belt.

Request for a quote

ERO JOINT .TANALS

France

Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The recommended minimum diameter for pulleys is 50mm. The mechanical joint system ERO Joint® WT is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® WT are lasting solutions. The ERO Joint® WT splice shape may be adapted in order to increase the mechanical resistance. ERO Joint® WT is the only one solution of mechanical belt fasteners in wide timing belts. The ERO Joint® WT wide timing belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

ULTRASense is a compact, airborne ultrasound sensor that connects directly to specific SDT instruments via a direct coupled LEMO7 input. It’s primary design and function is to detect sources of airborne ultrasound including positive and negative pressure leaks, electrical partial discharge, mechanical defects in belt drives, chain drives, and direct coupled shafts. ULTRASense detects signals generated by T-Sonic1 and T-Sonic9 ultrasound transmitters and is therefore applicable to tightness inspections.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PKO-SURA COMPANY

Russia

Starch molding machine is designed for production of fruit-jelly (including jelly candy), liqueur, fondant sweets and Korovka sweets by starch molding. The machine consists of a movable belt, a molding mechanism and a depositor mechanism. The tray is filled with starch which serves as a forming material. The confectionery mass is fed from the hopper to the dosing unit which performs deposition of sweets/molding the marmalade into molds formed in the starch layer.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

The DDA Direct Drive Motor is a rotary actuator that directly drives a rotary table with a motor without using any speed reducing mechanism such as a belt or reduction gears. Eliminating the speed reducing mechanism explains why high speed and excellent response can be attained with such a compact frame. The series includes models designed for high torque and high payload up to 90 or 270 kg. This makes it very easy, for example, to integrate rotary indexing tables in an automation system.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION The machine which works with motor–belt mechanism, ideal for the serial end milling operations on aluminum and PVC profiles precisely. High quality end milling operations by means of the adjustable motor speed thanks to the inverter and potentiometer. Practical change of cutter provides ease of operation Fixing the workpiece firmly and at square by means of the vertical clamps and adjustable horizontal supports Safety operations with safety guard Cutter storage location in front of the machine Robust machine stand and support arms in front of the machine to provide end milling of profiles up to 2.5 meters Practical cutter adjustment by means of the gap parts Max. end milling profile height (H): 210mm Max. end milling stroke (W) : 615 mm Max. saw blade diameter: Ø185 mm Max. tool height : 150 mm STANDARD ACCESSORIES • 12x pneumatic vertical clamps with adjustable pressure valve • 6 x adjustable horizontal supports • Air gun

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Good mechanical properties of a particleboard require core layers made of homogeneously distributed, consistent-quality particles. The mechanical forming heads by CMC Texpan are ideal because they always guarantee consistent particle distribution at the right time. They are called Cageformer heads. Features, function Upstream disc screen for discharging oversize or glue clots Metering bins with adjustable rakebacks Bin bottom belt with speed control belt scale Mechanical Cageformer head incl. 4-6 proled distributing rollers distributing plates 4 cage rollers Advantages No separation eect on the core-layer material Improved distribution in transversal direction Easy cleaning Variants, options Format adjustment forming chamber side wall adjustment recycling of the excess particles Inline correction of transversal distribution

Request for a quote

ERF GROUP

Turkey

ERF-CAT double suction centrifugal cell fans are produced in different sizes between 1.000m³/h and 20.000 m³/h flow rates. Cell panels are 20 mm thick and 70 kg/m³ density rock wool insulated. They provide maximum efficiency with low energy and vibration-free operation.

Request for a quote

DISPA MACHINE

Turkey

• Semi-automatic double miter for cutting profiles and solid material in steel and non-ferrous material and an excellent price-performance ratio • Manually swiveling saw frame with hydraulic clamping for optimal • Hydraulic clamping of the horizontal vise • Automatic saw frame raising on the cut end • Double speed motor 1.0/1.3 KW Gearbox • Sensitive cutting pressure regulation function of the material properties • Hydraulic-mechanical belt tension • Tape guide with hard metal pads sheets and rolls • Thermal overload protection and no-volt release • Automatic shut-off after cut end • Automatic belt break protection Driven

Request for a quoteResults for

Mechanical belt - Import exportNumber of results

24 ProductsCountries

Company type

Category

- Conveyor belts (10)

- Transmission belts (4)

- Flour milling - machinery and equipment (2)

- Machine tools, cutting - parts and accessories (2)

- Automation - systems and equipment (1)

- Bakery - machinery and equipment (1)

- Blades for saws and cutting machines (1)

- Confectionery - machinery and equipment (1)

- Packing and packaging - machinery and equipment (1)

- Sensors (1)

- Ventilators and fans - industrial (1)

- Wood veneer - machinery and equipment (1)