- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal strip coating

Results for

Metal strip coating - Import export

HFP BANDSTAHL GMBH & CO KG

Germany

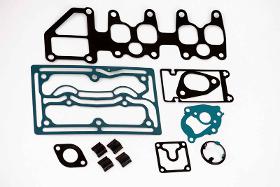

Our rubber-coated metal strips are used in numerous applications, such as engine and aggregate seals. In addition to NBR, we also coat metal strip with EPDM, NR, HNBR and FPM in thicknesses of 10 μm - 2 mm. The metal strips can also be coated with an anti-friction coating, which offers extremely high resistance to heat and special sliding ability. The resulting further processing quality enables them to be used wherever parts made of metal strip with sealing, sound-absorbing or vibration-damping properties are required. The very good bonding between elastomer and metal, combined with outstanding deep-drawing properties, shows the superiority of this coating. The metal strips can also be top-coated with decorative lacquers on both the metal and the rubber coated side (e.g. as a distinguishing feature in the company's own production for top and bottom sides).

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

In the field of plastics we offer metal strips with PVC plastisol and/or organosol coatings, as well as polyamide plastics. PP (polypropylene), PE (polyethylene), PC (polycarbonate), PET (polyethylene terephthalate) and PLA (polyactide), TPE (thermoplastic elastomer), TPU (thermoplastic polyurethane) and others. These can be produced with a layer thickness of 5-200 μm Depending on the plastic, higher layer thicknesses can also be achieved. In addition, most plastics can also be equipped with antibacterial properties; of course in all colour variations. Although a one-sided coating more common, we are able to apply the same and/or different plastic adhesives for both sides.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

An innovation for decorative applications is the stripe coating on our narrow Coil Coating line at First American. This is a complete coil coating process in which we are able to leave tightly toleranced, unpainted stripes on the carrier strip. These give the decorative effect to the finished article, while the coated areas are coated with an adhesive system (e.g. automotive trim material or white coating with a defined black stripe, etc.). As always, all metal strips available on the market can be used as metal carriers; all coatings can also be used. This leads to a smart product, allowing you a multitude of new, innovative applications.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Our special ability lies in the processing of metal strips pre-coated with adhesives. With this material it is particularly important not to damage the surface mechanically whilst at the same time not to impair the ability to bond. This skill enables us to supply stamped parts for bonding with rubber and/or thermoplastics, such as Vibration damping elements spring elements stabilizers functional parts components We guarantee a functional workability of the product for 6 months after delivery.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

In coil coating, an organic coating is applied to the surface of a metal strip in a continuous process. The HUEHOCO portfolio includes both decorative and weather-resistant coatings as well as system solutions for a firm bonding of the metal strip with various rubber compounds and/or various plastics. For technical applications, there are also high-temperature resistant and non-stick as well as anti-friction systems, directly rubber- or plastic-coated metal strips. Since 1989 we have been the first company in the world to offer our customers the opportunity to have their goods delivered "endlessly" wound with more than 200,000 metres in a single strip on metal or plastic spools. Depending on our customers' requirements, we can process all wrought aluminium alloys, stainless steels, steel grades and non-ferrous metals available on the market in various degrees of hardness.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

Here at Hamilton Precision Metals, we’re passionate about cold rolling metal strip in a diverse range of specialty alloys to meet your exacting specifications. Our extensive precision strip product range include stainless steel strip, nickel strip, titanium strip, copper based strip, cobalt based strip and many more alloys. We have the expertise to roll light gauge strip from 1.5 mm (.060”) down to 0.127 mm (0.005”). Broadest Range of Alloys We offer an extensive portfolio of almost every high performance alloy made today. Additional alloys are available upon request, contact us today! Stainless Steels Nickel Based Alloys Copper Based Alloys Cobalt Based Alloys Commercially Pure Titaniums Strain Gage: Constantan®, Evanohm®,

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products uses a wrought powder metallurgical process to ensure the highest purity finished products. Our main strengths lie in the processing of Nickel, Iron and Cobalt containing alloys amongst other available materials. The processing of these materials begins with the consolidation of powder through a roll compaction process and followed by a controlled atmosphere sintering. Further reduction of the material is performed solely under cold working temperatures to reduce the introduction of non-metallics and annealing is performed under controlled atmospheres. AMETEK Strip Products are produced in ranges between .002” (0.05mm) and .080” (2.03mm) thicknesses in a full range of tempers and widths to 22” (558.8mm) while maintaining special capabilities to produce materials outside of these ranges for special applications. This process lends itself to the production of small but easily reproducible lots of highly specialized alloys

Request for a quote

ROKVELAS, UAB

Lithuania

At given need our experts can invoke extensive subcontracting. Constructions can be: shot blasted and painted wet; galvanized in various ways;

Request for a quote

NANOPHYLL - SMART COATINGS

Canada

NanoPhyll’s PolyPhyll™ is a polymeric powder coating that prevents corrosion and fouling. It extends the life of heat exchanger plates, increases up time and reduces maintenance cost. Thermally conductive Corrosion and chemical resistant Superior adhesion to metals Durable (1500+ hrs in 80% Sulfuric acid at 85°C without any damage) Operate up to 260 degrees Celsius

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

In addition to laser cutting, edging and welding, we at W & K Metallverarbeitung also offer various services in the field of post-processing and surface treatment either internally or through reliable external partners. We execute all requirements according to your required factory standard. Would you like a final assembly of your products? This is also possible with us. For coating and surface treatment, we work together with high-performance partners. • Powder coating (maximum component size 1.6 x 3.0 x 8.0m (W / H / L)) Galvanized galvanizing (blue, yellow or black chromating, max. Length of the component 3,000 mm) • Hot dip galvanizing (spin-galvanizing, high-temperature galvanizing, maximum component length 9,000 mm) • KTL coating • rays Which surface do you want? We are happy to help!

Request for a quoteResults for

Metal strip coating - Import exportNumber of results

11 ProductsCompany type