- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal tanks

Results for

Metal tanks - Import export

NC MANUFACTURING AND ENGINEERING

Turkey

Fuel tanks used in diesel generator applications are classified as daily tanks and main fuel tanks depending on generator fuel consumption and capacity. Fuel tanks are available in a wide range of versions, from prismatic or cylindrical, above-ground or underground, single-walled or double-walled, horizontal or vertical versions, to suit specific application.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

We are specialized to design and fabricate carbon, stainless or exotic steel pressure vessels mainly for oil&gas, petrochemical and power industries in accordance with ASME Sec VIII Div.1 and EN Norms with CE mark. Most of the industrial processes need to store fluids and materials of different kinds and with different purposes.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Special features of the Lipp welding technology are the automated on site construction of above the ground cylindrical tanks made of various grades of duplex steel, stainless steel and black steel. Moreover, the technology also incorporates the post treatment of the weld and a visualized welding monitoring and the technical documentation of the process. Due to the flexible and mobile concept of the equipment, the installation can either be done on greenfield construction sites but also inside buildings or in places with limited access and working space.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

FLEXIBLE, SAFE AND PROVEN THE WORLD OVER – THE LIPP DOUBLE SEAM SYSTEM Conventional systems are often unsuitable for the optimum, safe storage of solid or liquid substances and their use can result in premature corrosion, leaks and problems with safety. Flexibility is another important factor. Tanks must be flexible in terms of size and substrate and optimally adaptable to the local conditions. THE LIPP DOUBLE SEAM SYSTEM HAS PROVEN ITSELF TIME AND TIME AGAIN ALL OVER THE WORLD FOR MORE THAN 45 YEARS MULTI AWARDED. The principle of the LIPP Double Seam System is as follows the edges of steel strips are folded over together twice, connecting them together in such a way that even aggressive liquids inside the tank cannot find any surfaces to attack. The result corrosion is prevented and maximum leak tightness is achieved.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The reference information is then applied during service and inspection visits to ensure that the expected performance levels are being met. All inspections are carried out by fully qualified Lipp professionals, who utilise the latest analytics equipment. Efficiency tests can be run on each system and cross referenced – helping highlight any operational issues that may have occurred. This comprehensive analysis further notifies Lipp and the end user which parts of the system may need particular attention or replacement. Qualified Lipp technicians also have the skills needed to deal with more specialised installations, such as anaerobic digestion tanks for biogas production. By providing the same level of technical proficiency as the original installation team, Lipp safeguards the quality level of maintenance activity and the tank itself. Lipp technicians also impart knowledge and training to the end users, so that everyone can become familiar with their system

Request for a quote

NOVELTY STEEL

Turkey

A pressure vessel is defined as a container with a pressure differential between inside and outside. The inside pressure is usually higher than the outside, except for some isolated situations. The fluid inside the vessel may undergo a change in state as in the case of steam boilers, or may combine with other reagents as in the case of a chemical reactor. Pressure vessels often have a combination of high pressures together with high temperatures, and in some cases flammable fluids or highly radioactive materials. Pressure vessels are used in a number of industries; for example, the power generation industry for fossil and nuclear power, the petrochemical industry for storing and processing crude petroleum oil in tank farms as well as storing gasoline in service stations, and the chemical industry (in chemical reactors) to name but a few.

Request for a quote

NOVELTY STEEL

Turkey

Stainless steel is an alloy of steel with chromium content that is a better resistant to rusting and corrosion compared to carbon steel. For storing corrosive chemicals and liquids, often traditional coatings of carbon steel does not offer enough protection. For such material, stainless steel tanks offer more durable and long lasting storage. Novelty Steel is an experienced fabricator of steel tanks. With our modern CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke steel frames according to the EN 1090-2 European Norms. Some examples of the stainless steel tanks are: * Fixed-roof tanks * External floating roof tanks * Internal floating roof tanks * Domed external floating roof tanks * Horizontal tanks * Pressure tanks * Variable vapor space tanks * LNG (Liquefied Natural Gas) tanks

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel fabricates carbon steel and stainless steel tanks; Fixed-roof tanks External floating roof tanks Internal floating roof tanks Horizontal tanks Pressure tanks Variable vapour space tanks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TANKS AND SYSTEM SOLUTIONS FOR SOLID, LIQUID AND GASEOUS SUBSTANCES As a tank construction specialist, we offer quality tanks and system solutions in steel for industry, communities and agriculture. Our unique Lipp System construction method ensures the highest levels of quality when storing solid, liquid and gaseous substances. Your project, from an individual tank to a complete turnkey plant, will be completed with the emphasis firmly on longevity, flexibility and individual adaptability. With over 55 years experience in plant and tank construction, LIPP GmbH is a family company which is active worldwide. We have carried out over 10,000 projects world wide and own over 170 pioneering patents.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

INDIVIDUAL SERVICE FOR EVERY CUSTOMER After installation of a Lipp tank system, the primary concern is safeguarding the market leading performance of all the associated parts. This process begins from the very first consultation – as Lipp produces efficiency estimates and process diagrams as a comparison point. Lipp understands the particulars of every system that it installs, helping to bring a personalised service and a one stop shop to every customer

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

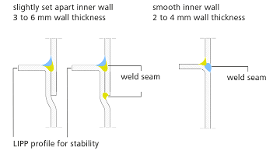

LIPP welded tanks are erected using the LIPP Welding Technology, a unique method of construction enabled by a custom automated rig designed and manufactured by LIPP. This procedure can claim a number of advantages over other traditional welding methods. Firstly, the unique steel profile increases stability and so reduces material costs at the same time. Secondly, the automated endless tape process continually welds layers below in a rotational cycle and reduces the number of on site workers. LIPP Welding Technology enables welding both black steel and stainless steel of different grades, allowing numerous applications. LIPP aims to increase construction efficiency through the implementation of unique techniques and technology, ultimately benefiting customers via a cost effective system. The key facets for the construction of a LIPP storage system are automation, continuously variable tank dimensions, reduced space requirements for onsite construction and increased worker safety.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP foremost engage with clients to build systems tailored towards their needs. Each tank is custom specified for each application, following a customer consultation – as construction materials, coatings and sealants differ greatly depending upon the stored media. Tank integrity, stability and corrosion resistance are paramount in any LIPP installation – which is achieved through a detailed understanding and advanced construction methods. This means water, aggressive liquids, solids, gaseous media and other substrates are provided for with equal expertise. Performance models and efficiency calculations also provide the customer with an insight into the future performance of their system. In terms of materials, LIPP provides the most appropriate metallic materials solution for each application. The entire spectrum is catered for; from specific purpose graded steels right up to high quality stainless steels.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

HIGH QUALITY AND SAFETY STANDARDS LIPP brings over 55 years of experience in the field to every project, helping to meet the most demanding safety and quality standards that will deliver profitability and reliability. Proven technologies, such as the spiral LIPP Double Seam System and Verinox material, have been developed and proven to deliver both flexible and efficient storage systems. Tanks are erected via a construction method exclusively employed and developed by LIPP, delivering customizable tanks for any application with a volume of 10,000m3 or more. Perfectly matched to the purpose of each installation, each tank incorporates large volume with a customized interior. LIPP understands that adaptability provides solutions for various applications and requirements – so customers can even specify their own services to lower the total cost of investment.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

With such flexibility, the sales team at Lipp can enable any customer to specify exactly what is needed for their installation. From complete, turnkey systems to individual components and accessories – Lipp can support customers whatever their requirements. Consultation is a primary objective for Lipp before any work is undertaken. Lipp provides diagnostic tests, efficiency calculators and flow sheets to visualise a tank system and inform the customer of the performance they can expect. This is especially useful for anaerobic digestion – where Lipp experience supports the efficiency and safety of the system from design through to construction. Particular attention is always paid to the content to be stored within the storage system, which allows Lipp to offer customers the chemically stable materials and accessories to get the most from their storage tanks and digesters. Fundamentally, Lipp’s focus on the customer allows consultation and sales to be perfectly integrated

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TAILOR MADE SOLUTIONS As a family owned company that offers a unique tank storage system to customers across the world, Lipp knows the high value of effective communication and customer support. Whether consulting with a Lipp specialist on a tank system design or ordering extra accessories for an installed system, the same professional help and guidance is always available. Lipp focuses on providing the optimum solution for the user, entirely customisable and ultimately efficient. Lipp will always recommend solutions that will increase the performance of a tank system while also ensuring – that it is the most suitable solution for the customer.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Lipp systems are modular and can be extended, modified or integrated into existing systems WITH EASE. Biogas plants from Lipp are based on the so called, wet fermentation. Through a 2 stage process, i.e., via regulation by an upstream hydrolysis stage or other substrate pre treatment, input materials are prepared so that the anaerobic process can run optimally in the digester. Since it is the most flexible and the biological processes are best kept controllable Lipp favours the SBR process. This is also particularly suitable for anaerobic wastewater treatment, sludge digestion and is also used in agricultural biogas deposits. This means first that Lipp biogas plants are substrate flexible and allow an intensive use of the available digester area. Secondly, that with low self sustaining energy requirements, a high degradation rate is achieved. It is interesting to note that Lipp’s digester can be operated not just in the SBR process (Sequence Batch Reactor).

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

BIOGAS FOR INDUSTRY, MUNICIPALITIES AND AGRICULTURE In addition to tank construction, LIPP built the first biogas plant in Germany in the 70’s. Furthermore, LIPP was one of the first companies to develop and sell small biogas plants in the early 80’s. By steady advancements in production technology and the materials used, as well as extensive experience in process engineering LIPP has installed in collaboration with its partners, hundreds of biogas plants in Germany and worldwide. The majority of these projects are still in operation and ensure proof of the high quality and the technical and economic performance of Lipp’s system solutions. LIPP provide system solutions for biogas production in the following areas APPLICATIONS anaerobic wastewater treatment plants waste fermentation plants sewage sludge digestion agricultural biogas plants

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR THE STORAGE OF CEREAL PASTE AND SUGAR BEET Lipp plans and sells storage systems for biomass such as cereal paste or sugar beet under the brand names LIGAVATOR and BETAVATOR. These systems are generally gas tight and both roof and container base (optional) are made of solid stainless steel, since the stored media can give rise to very aggressive juices and gases. With this type of storage the substances are preserved and can be used over a very long period. Automatic withdrawal and substrate delivery can also be installed in the following systems by an appropriate control system. APPLICATION EXAMPLES AND REFERENCES In addition to pure crop storage, the Lipp LIGAVATOR / BETAVATOR systems are mainly used as substrate storage for agricultural or industrial biogas plants, and are installed before the fermenter for appropriate substrate supply. They allow largely automated control of a biogas plant, as there is no need for a regular manual substrate supply.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR THE STORAGE OF SLURRY Following the further development of the Lipp dual seam system and the container material it was possible not only to build silos for bulk materials, but also silos for the storage of liquids, such as liquid manure. Since slurry is also rather more aggressive and can attack concrete or similar vessels, especially over the years, Lipp always offers its system solutions for the storage of slurry in principle in V2A stainless steel (1.4301), when it is clear that the tank will remain open. Possible changes are also taken into account with the customer during the planning process and in case of a future modification of the slurry tank consideration is given to an alternative material (V4A) or the possibility of a subsequent roof construction. Thus, the container retains its flexibility and can later be converted into a fermenter, secondary fermenter or other container.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Settling and floating layers are avoided by horizontal and vertical mixing. Before plant construction, coordination takes place with the future plant operator to determine the optimum stirring technology based on the respective substrates. Operational safety is ensured by the closed reaction chamber, the external drive for the agitator and the externally mounted electric drives. Variable dimensions and substrate flexible stirring technology also allow the use of difficult substrates. The wall heating system, externally mounted on the fermenter wall, ensures optimum fermentation conditions and a high gas yield. FAST ASSEMBLY – LESS COST Low installation costs are possible by using the Lipp dual seam system and on site production. If the foundation slab is provided along with assistance during assembly, costs fall still further.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

OVER 45 YEARS’ EXPERIENCE IN AGRICULTURAL BIOGAS PLANTS When deciding on a biogas plant, the manufacturer’s experience should be prioritised. It is not just a question of economic viability, but essentially of optimal design. Lipp GmbH has over 45 years’ experience in this area and is continually developing the technology. The biogas plants manufactured by Lipp are based on a rounded plant concept in terms of consulting, development, manufacture and assembly. With its comprehensive expertise and the use of proven technologies such as the Lipp dual seam system, the material Verinox, and high quality accessories, the highest level of quality is achieved with optimum economic efficiency.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Gas storage systems by Lipp have been successfully installed in more than 300 projects in Germany and worldwide. The gas storage capacity extends from 30 to 5,000 m³. The gas resistant PVC gas holder is protected by a galvanised steel cylinder. The self supporting roof is made of 1.4301 high grade stainless steel. The Lipp gas holder is offered as a complete system, including sensors and built in parts as well as steel construction, and can be easily integrated into an existing system. The main area of application of the Lipp gas holder is municipal waste water treatment plants and landfills which want to balance out fluctuations in gas production and at the same time need a buffer store for possible downtimes. A further gas holder may also be of interest for direct marketing of biogas, where feed in at certain times is necessary. The Lipp gas holder is especially attractive when considering the fact that electricity cannot be stored. But (bio) gas, which is used for power generation

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR GAS STORAGE With the Lipp gas holder Lipp offers a tried and tested system solution which is complete in itself, for unpressurised storage of biogas, sewage gas and landfill gas. This solution is chiefly used for municipal waste water treatment plants and landfills. Due to its design, as well as high functional and operational safety, it also ensures low maintenance costs over a very long service life. This is mainly because the sensitive gas holder is protected against UV radiation and other environmental influences by a steel container manufactured with the Lipp dual seam system. Furthermore, this construction method allows an exact leak test and highly accurate metrological monitoring of the gas fill level. Both aspects are essential for safe and efficient plant operation. With certification according to § 19 WHG for Lipp GmbH and DVGW approval of the gas storage tank, further conditions are met for use in municipal waste water treatment plants.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Lipp tank and system solutions for municipal waste water treatment have been realised in close cooperation with well known design companies and end customers since the 1980s. In addition to municipal waste water treatment plants in Germany, Austria, Switzerland, France and other European countries, the Lipp system has already been successfully installed in many Asiatic projects. Lipp waste water tanks are offered in variable sizes and with individually adapted features (material, covers, additional equipment). Our success lies in professional management and close cooperation with all stakeholders over the entire project period. Reliable tank solutions, timely installation and numerous reference plants both in Germany and worldwide make Lipp an important partner in municipal waste water treatment.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR MUNICIPAL WASTE WATER TREATMENT Lipp has for many decades been an established partner of municipal waste water treatment plants, engineers and general contractors in the field of tank and system solutions for municipal waste water treatment. Due to their method of construction as well as flexibility in the choice of materials and ideal diameter – height ratios, Lipp tank and system solutions are especially suitable for the needs of small to large sewage treatment plants. They are ideally tailored to one another, but may also be embedded as individual island solutions into existing systems and are therefore equally popular with planners and end users alike. The stainless steels used and the double seaming guarantee maximum water tightness and durability with low maintenance for a wide variety of waste waters, slurries, process liquids and gases. The versatility in terms of the system solutions offered for municipal waste water treatment plants

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

As well as the high quality, end customers and engineering offices alike appreciate Lipp’s process expertise and close, professional working methods. In addition to individual planning and timely installation, the service package is also rounded off by extensive tank inspections. Depending on customer requirements, Lipp offers its partners support in the preparation of necessary planning criteria such as design, heat and energy calculations etc. Lipp’s objective is to be the most reliable partner for municipal sewage treatment plants and for engineers for municipal waste water treatment and sludge digestion. To achieve this, in addition to the product quality, the professional, timely and economical completion of projects is constantly being improved. In order to work with end users and engineering offices as effectively as possible, the technical process expertise is also being constantly expanded by the ongoing qualification of employees and high investments in research.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR SEWAGE SLUDGE DIGESTION In the municipal sector, the focus is on the production of biogas from sewage sludge. The aim is to make the energy potential of the primary and secondary sludge from anaerobic sludge digestion usable. On the one hand heat and electrical power is obtained for operation of the sewage plant. On the other hand, the sludge is conditioned so that the other aerobic process stages can run more efficiently and thus more cost effectively. The Lipp KomBio reactor has established itself as an ideal solution in the municipal sector due to its construction and long service life and has been successfully installed in hundreds of plants at home and abroad. Thanks to the application of the SBR process in our digesters, and the tank geometry and construction, it is possible to make optimum use of the low energy potential of the sewage sludge and operate sewage sludge digestion economically.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Beside the protection against external effects as UV or other external effects which could damage the foil, the unique construction enables a reliable and measureable leak test as well as an accurate filling level measurement at all times. Compared to low pressure systems and double membrane gas accumulators the Lipp system has very low operation and maintenance costs.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

ATMOSPHERIC PRESSURE, MAINTENANCE FREE AND PROTECTED AGAINST EXTERNAL EFFECTS The pressureless gas storage system of Lipp is used for the storage of gas produced on landfill sites, waste water treatment plants and also as external storage on biogas plants. The system is determined by its robust and technical advanced construction where the gas balloon is protected by a galvanized steel tank. This protects the balloon against UV light and also other external factors. The system is mostly utilized at landfill sites or WWTP to buffer the gas before its further processing. The experience gained during the past decades has improved the complete system and the single components and makes it a perfect choice for end users and general contractors.

Request for a quoteResults for

Metal tanks - Import exportNumber of results

194 ProductsCountries

Category

- Tanks, metal (170)

- Storage tanks (18)

- Pumps (3)

- Vats, metal (3)

- Water treatment, industrial - systems and equipment (3)

- Cisterns, metal (2)

- Industrial containers (2)

- Industrial sheet metal work (2)

- Tanks, plastic (2)

- Cleaning, industrial (1)

- Conveyors, overhead and floor (1)

- Finished Metal Products (1)

- Food - import-export (1)

- Fuel oil (1)

- Measurement and control instruments (1)

- Measurement and regulation equipment and instruments - temperature (1)

- Olive oil (1)

- Paints and varnishes (1)

- Screws (1)

- Trailers (1)