- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- reactors

Results for

Reactors - Import export

KASAG SWISS AG

Switzerland

Pressure vessels/containers and reactors must meet the highest quality requirements. The pressurized objects are designed at KASAG according to the relevant regulations and subsequently produced, with great enthusiasm, using the most modern technology. Stainless steel and special materials, such as duplex and nickel-based alloys (Hastelloy, Inconel) are processed. All our production experts have the mandatory certificates, and have mastered the welding process MIG, MAG, TIG, Plasma and Orbital and work solely with certified welding consumables. The pressure vessles and chemical reactors are finally polished, pickled, passivated and tested using non-destructive test methods. KASAG products meet all your standards.

Request for a quote

MIX SRL

Italy

Main features • Management of the process time and temperature through the heat exchanger • Short mixing time • Extremely high mixing quality • Batches with repeatable results • Mixing ratio 1/100.000 • Coefficient of variation (CV): ≤ 3 % • Low maintenance Techanical features • Batch size: from 65 to 28.000 liters (net) • Cylindrical mixing chamber • MIxing tools: ploughshare / ploughshare with toothed design / Mix Paddle / Mix Paddle with toothed design • Material of costruction: carbon steel / Hardox 450 / AISI 304 / AISI 316 / AISI 316Ti • Inspection door complete with safety electric lock • Discharge door with round profile, building the bottom side of the mixing chamber • Rotor shaft with turned and coaxial ends • Rotor shaft sealing system with packing seals and wear resistant ferrules to protect the rotor shaft, prepared for flushing with air / nitrogen • Heat exchanger on mixing chamber for heating / cooling processes

Request for a quote

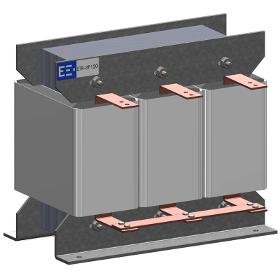

EDIT ELEKTRONIK SIST SAN VE TIC LTD STI

Turkey

They are filter reactors used to reduce the current harmonics (THDI) in the network installation to the values required by the standards. It is used in Reactive Power Compensation systems to limit the overcurrents that occur during the switching of the capacitor groups and to protect the capacitors. ●Harmonic Filter Reactors ●Copper and Aluminum winding ●High efficiency sheet core ●Varnishing under vacuum ●Oven drying at high temperature ●Three Phases and single Phase

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

Lödige DRUVATHERM® reactors are batch reactors. Rotating mixing elements adapted to the specific process, installed in a cylindrical drum equipped with a temperature control jacket, create a three-dimensional product movement. The resulting contact frequency of the reacting agents with each other leads to a more effective conversion with a higher yield. The mixing elements ensure high contact frequency of the reacting agents with each other and intense contact of the reacting agents with the heated or cooled vessel wall. This makes reactions in homogeneous and heterogeneous phases possible in practically all combinations (solid/liquid/gaseous). The production consistency can be anywhere along the spectrum of liquid to pasty to lumpy to pourable. High-speed rotating choppers installed on the side of the machine drum perform additional mixing work to distribute the reacting agents.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

Lödige DRUVATHERM® reactors are batch reactors. Rotating mixing elements adapted to the specific process, installed in a cylindrical drum equipped with a temperature control jacket, create a three-dimensional product movement. The resulting contact frequency of the reacting agents with each other leads to a more effective conversion with a higher yield. The high-speed mixing elements ensure high contact frequency of the reacting agents with each other and intense contact of the reacting agents with the heated or cooled vessel wall. This makes reactions in homogeneous and heterogeneous phases possible in practically all combinations (solid/liquid/gaseous). The production consistency can be anywhere along the spectrum of liquid to pasty to lumpy to pourable. High-speed rotating choppers installed on the side of the machine drum perform additional mixing work to distribute the reacting agents.

Request for a quote

GEO TEKNO LTD. CO.

Turkey

Stainless steel or carbon steel reactors, which can operate under high pressure and vacuum, are often used in the chemical and food industries. All of the GEO reactors with heating or cooling jackets, suitable for pressure and high temperatures, with high corrosion resistance are manufactured in accordance with international standards. 1 – 80 m3 capacity range Heating and cooling: Jacketed or half-pipe serpentine on the outer body, serpentine from seamless pipe on the inner body Thermosiphon cooled mechanical seal or soft seal Dismountable Mixer wings and baffles Specially designed hive construction With Filled Columns or Condensers, Heat Exchangers Delivered with CE certificate if requested.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Heating and cooling system products like (Ointments, Creams, Ketchup, mayonnaise …etc ). High quality of Homogenization Vacuum and pressure atmospheric system Product recirculation system equipped with European pumps and valves for a better performance Sight glass Viewing ports Double jacket Compact design Homogenizer with pump functionality. Blades designed to mix and knead. CIP system Steam system Vacuum pump Agitator with high tech anchor design Automatic open and closing system HMI and PLC with SCADA system Available certification up on your request: UL, CE, cGMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

PATENTED DIGESTER WITH INTEGRATED GAS ACCUMULATOR LIPP KomBio Reactor for industry and local authorities The innovative and outstandingly economical solution for energy production at biogas plants and stabilisation of sewage sludge has been in use in many countries for over twenty years. Quick realisation, low investment costs, high operating safety and long service life are all characteristics that speak for themselves. The system is suitable for small and large plants and complies with industry standards. KEY BENEFITS Production of renewable energy and reduction of fossil CO2 emissions Low noise emissions Flexibility with regard to substrate composition Compact and space saving with minimal pipeline construction High functional safety Steel roof (can be insulated) to protect against the weather Individually customisable for intended application Good insulation reduces heating demand Patented stirring systems Fast construction with production on site Low investment costs

Request for a quote

CTRA

Tunisia

CTRA produces a wide range of boiler-made equipment for chemical processing, including reactors, columns, decanters, mixers, gas coolers, gas scrubbers, odour scrubbers and absorbers, as well as their internal equipment. All this boilerwork is designed by our departments to meet the dynamic and hydrostatic loads required by the various processes. Thanks to the development and mastery of materials, CTRA is able to design a wide range of boilerwork, up to 6 m in diameter, to withstand the most corrosive fluids, whether they operate in a vacuum or at high pressure, from 50°C to 200°C.

Request for a quote

KASAG SWISS AG

Switzerland

Reactors must meet the highest quality requirements. The pressurized objects are designed at KASAG according to the relevant regulations and subsequently produced, with great enthusiasm, using the most modern technology. Stainless steel and special materials, such as duplex and nickel-based alloys (Hastelloy, Inconel) are processed. All our production experts have the mandatory certificates, and have mastered the welding process MIG, MAG, TIG, Plasma and Orbital and work solely with certified welding consumables. The pressure vessles and chemical reactors are finally polished, pickled, passivated and tested using non-destructive test methods. KASAG products meet all your standards.

Request for a quote

NOVELTY STEEL

Turkey

A chemical reactor functions as an enclosed vessel where chemical reactions occur. It's crucial for process designers to ensure the reaction proceeds efficiently toward the desired product, maximizing yield while minimizing costs associated with procurement and operation. Operational expenses encompass factors like energy input and disposal, raw material costs, labor, and other associated charges. Typically, reactants and products within the reactor are in fluid form, either gases or liquids. Continuous reactors maintain a constant operational state, while batch reactors undergo transient operation. Transient operation occurs when a reactor is activated for the first time or following a shutdown, with critical process variables fluctuating over time.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® PreInsertion Resistors are used for limitation of transients during energisation process of transformers and HVDC VSC converter applications. CSN® Discharge Resistors are used for discharge of Capacitors, reactors and superconducting magnetic field coils. They are characterized by a high dielectric strength and energy absorption capacity. CSN® PreInsertion or Discharge Resistors are designed and manufactured individually to customer requirements and specific application.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Stainless steel digester with a digester chamber volume of 100 to 2500 m3 Integrated gas accumulator – fixed in gutter for high operating safety Optimised diameter to height ratio for optimum mixing and minimal stirring Low maintenance, external panel heating system Flexible stirring technology which can be adapted to the substrate and digester Stirring technology can be maintained without having to empty the tank

Request for a quote

EBINGER KATALYSATORSERVICE GMBH & CO. KG

Germany

Step by step: From taking the test sample up to the large-scale regeneration of your catalysts Stept 1: Sample taking Let us know when a sample can be taken from the SCR reactor. We will gladly do this for you. Step 2: Analysis Why is the catalyst no longer active? By an analysis of the catalyst sample we get a general overview about the chemical condition of the catalytyst. Step 3: Diagnosis By evaluation of the chemical analysis we find out the cause of the inactivation and determine the necessary regenerations steps. Step 4: Test Regeneration / Measurement Regenerations are executed under laboratory conditions to determine the ideal regeneration procedure. Activity (k) and SO2/SO3 conversion rate will be measured after this in the bench scale. Guarantees The results of the test regeneration are the basis for the guarantee values, which are part of a regeneration offer.

Request for a quote

EDIT ELEKTRONIK SIST SAN VE TIC LTD STI

Turkey

ETR Galvanic Isolation Transformers provide isolation between network installations and sensitive electronic loads. Insulated aluminum or copper windings are wound on a high efficiency sheet core. ETR transformers are vacuum-impregnated varnished and high-temperature dried to ensure quiet and moisture-proof operation. It is safe and long lasting.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

O.M.C. COLLAREDA S.R.L.

Italy

Aerobic type plants. Total Oxidation Activated Sludge Reactor. Moving Bed Biofilm Reactor. Combined Reactor. Membrane Bio Reactors. Water and Air Mixing. Dissolved Air Flotation unit.

Request for a quote

BASE GROUP SP Z O.O.

Poland

We made a reactor for our client (offshore industry). The construction was made of stainless steel. The reactor uses technology based on ballast water. The reactor purifies of water from algae or bacteria by pressure reduction.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The POLY-AT design offers exceptional flexibility when it comes to installations beneath the polymer melting reactor. Customers can choose from three different flange geometries to ensure they are always benefiting from the best combination of reactors and pump flanges from both a technical and economical perspective. The new gear geometries facilitate differential pressures of up to 320 bar for selected pump sizes. What’s more, the new design is rounded out with the usual variety of different material combinations. The most common of these combinations has to be a stainless-steel or carbon-steel housing with tool steel or aluminium-bronze friction bearings.

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

The Large Volume Processor program consists of horizontally arranged, heated reactors with twin (co- or counterrotating) shaft which provide intensive mixing and kneading. The highly versatile large volume processors Reasil and Reacom are characterised by the following advantages: Very large volumes The highest viscosity melts (up to 15,000 Pas) and solids can be processed efficiently Low shear processing Long residence times are achieved economically Mixing, devolatilization, reaction and phase change (from melt to solid) can take place in the same machine. A successful devolatilization or reaction system consists of the right processor design integrated with properly engineered subsystems. SMS can provide a complete system, including installation and start-up services, or full engineering and design documentation to allow you to add the necessary subsystems for our high volume processors.

Request for a quote

FLOWLINK BV

Netherlands

High-pressure gear pump for the discharge of medium to high viscosity media from the reactor.

Request for a quote

PLANT OF TECHNOLOGICAL EQUIPMENT, LLC

Ukraine

We produce capacitive equipment of various purposes and designs, including stainless steels, and with weighting equipment, with a volume – from 1 to 50000 Equipment is provided with a frequency converter or fixed speed mixer, with a heating or cooling jacket, with the installation of electrical heating with temperature sensors and thermostat or according to your heating medium, cooler, vertically or horizontally standing, on the supports or on brackets for the overpass, with or without weighing equipment, with the number of hatches you need for maintenance and nozzles for supply and withdrawal of the product, with or without weight equipment. It is possible to complete with the cleaning heads and the flyover for maintenance.

Request for a quote

ATILIM MAKINA

Turkey

Reactor, storage tanks, silos, reactors, blenders, mixers, mixer blades, turnkey resins and chemical plants, filters, heat exchangers, boilers, basketmill, basket mills, paint finishes, polyester plants, bio diesel plants, thin film evaporator, alkyd plant , Pva plant, styrene acrylic plant, mixer blades, storage tanks, plasticizers plant (DOP, DOTP, DOA, DINP, DIDP, TOTM), urea formaldehyde plant, autoclave, bunker, boiler washing machine,water solvent based paint factory,Pilot production plant, pilot reactor, pilot blender, pilot mixer mixer, pilot exchanger, pilot PVA, pilot alkyd plant, pilot plastic plant, pilot polyester plant, pilot bio diesel plant, pilot urea formaldehyde plant, pilot DOP, pilot DOTP, pilot DOA, pilot DIDP, pilot TOTM facility,universal pilot production plant,rashing Ring,Scrubber,Solvent based thermoset acrylic resin plant,Pipe heat exchanger,Chemical reactors,Reactor manufacturers,Companies manufacturing reactors,paste press machine turbo mixer,hot melt glue

Request for a quote

ATILIM MAKINA

Turkey

Reactor, storage tanks, silos, reactors, blenders, mixers, mixer blades, turnkey resins and chemical plants, filters, heat exchangers, boilers, basketmill, basket mills, paint finishes, polyester plants, bio diesel plants, thin film evaporator, alkyd plant , Pva plant, styrene acrylic plant, mixer blades, storage tanks, plasticizers plant (DOP, DOTP, DOA, DINP, DIDP, TOTM), urea formaldehyde plant, autoclave, bunker, boiler washing machine,water solvent based paint factory,Pilot production plant, pilot reactor, pilot blender, pilot mixer mixer, pilot exchanger, pilot PVA, pilot alkyd plant, pilot plastic plant, pilot polyester plant, pilot bio diesel plant, pilot urea formaldehyde plant, pilot DOP, pilot DOTP, pilot DOA, pilot DIDP, pilot TOTM facility,universal pilot production plant,rashing Ring,Scrubber,Solvent based thermoset acrylic resin plant,Pipe heat exchanger,Chemical reactors,Reactor manufacturers,Companies manufacturing reactors,paste press machine turbo mixer,hot melt glue

Request for a quote

ATILIM MAKINA

Turkey

Reactor, storage tanks, silos, reactors, blenders, mixers, mixer blades, turnkey resins and chemical plants, filters, heat exchangers, boilers, basketmill, basket mills, paint finishes, polyester plants, bio diesel plants, thin film evaporator, alkyd plant , Pva plant, styrene acrylic plant, mixer blades, storage tanks, plasticizers plant (DOP, DOTP, DOA, DINP, DIDP, TOTM), urea formaldehyde plant, autoclave, bunker, boiler washing machine,water solvent based paint factory,Pilot production plant, pilot reactor, pilot blender, pilot mixer mixer, pilot exchanger, pilot PVA, pilot alkyd plant, pilot plastic plant, pilot polyester plant, pilot bio diesel plant, pilot urea formaldehyde plant, pilot DOP, pilot DOTP, pilot DOA, pilot DIDP, pilot TOTM facility,universal pilot production plant,rashing Ring,Scrubber,Solvent based thermoset acrylic resin plant,Pipe heat exchanger,Chemical reactors,Reactor manufacturers,Companies manufacturing reactors,paste press machine turbo mixer,hot melt glue

Request for a quote

BÜCHI AG

Switzerland

The temperature of jacketed reactors can be controlled by TCUs (temperature control unit) large central heating/cooling units with secondary systems for individual reactor temperature control process steam (in case of large metal reactors) Our jacketed reactors are typically temperature controlled using heat transfer oil and TCU or central heating/cooling units. The heat transfer oil which is pumped through the jacket of the reactor controls the process temperature inside the reactor. The temperature range of the heat transfer oil spans from -80°C up to 300°C (depending on the heat transfer oil used).

Request for a quote

BÜCHI AG

Switzerland

Laboratory pressure reactor system - comfortable and simple operation Reactor volume: 0.25 to 5.0 liter Pressure: -1 (FV) to +60 / 200 bar Temperature: -20 °C to +250 °C Material: Borosilicate glass 3.3, stainless steel, Hastelloy® Other materials, pressures & temperatures are available. This multipurpose pressure reactor system is designed for the use of interchangeable glass and steel pressure vessels. Safety features guarantee safe reactions under pressure. The glass reactors ensure high resistance against acids, while allowing visual process control and monitoring. This is also possible under high pressure by using steel pressure vessels with sight glasses. Various low to high torque magnetic drives ensure efficient mixing and stirring low to high viscosity process media as well as excellent heat transfer. The modular setup of the polyclave system allows changing or upgrading for new tasks at any time.

Request for a quote

BÜCHI AG

Switzerland

Pressure reactor for kilo labs and small-scale production Reactor volume: 20 to 500 liter Pressure: -1 (FV) to +200 bar Temperature: -20 °C to +300 °C Material: stainless steel, Hastelloy® Other materials, pressures & temperatures are available Buchi pilot plants are built for pressure reactions as well as for reactions under full vacuum. Different technologies and materials are used, depending on the requested process and process media. Pilotclave pressure reactors range from 50 - 500 liter and are all customized. To quote such systems we require detailed specifications. Safety is important with such larger scale systems, especially when doing hydrogenations and other reactions under higher pressure. The degree of automation and process control vary from simple data collection to complete automation of the system. In most cases, the reaction vessels are jacketed steel or Hastelloy® reactors.

Request for a quoteResults for

Reactors - Import exportNumber of results

90 ProductsCountries

Category

- Chemical and pharmaceutical industry - machinery and equipment (32)

- Electronic components (11)

- Chemical industry - machinery and equipment (7)

- Electrical & Electronic Components (4)

- Chemistry - laboratory products (3)

- Oiling - machines and systems (3)

- Electric transformers, converters and rectifiers (2)

- Gas and oil - exploitation (2)

- Mechanical engineering - custom work (2)

- Pipes and tubes, stainless steel (2)

- Storage tanks (2)

- Tanks, metal (2)

- Air filtration equipment (1)

- Boilerwork (1)

- Chemical catalysts (1)

- Cookers (1)

- Filtering equipment and supplies (1)

- Gear pumps (1)

- Laboratory equipment and instruments (1)

- Mixers (1)