- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheet metal

Results for

Sheet metal - Import export

IDEMAG

Spain

The magnetic sheet floaters are designed for separation of magnetic steel sheets, clean , oily or sticky sheets. They help boost press and press brake production by eliminating the need to fumble with thin oily sheets. It also operates in automated systems. For a good selection of magnetic floater in the separation of plates, first of all we should know the thickness of the sheets, since it is a critical input to do a good job. One thing to bear in mind is that the magnetic float IDG.FS.RB shall be 90 mm higher than the stack of sheets to be separated. Construction features: * Stainless steel case. * Construction of the magnetic circuit with powerful permanent magnet, which can not be demagnetized. * High resistance welded box. * Threaded holes in the mounting base for a quick assembly * Ceramic or Rare Earths magnets. * Non-standard size. * Sizes and configurations according to customer characteristics. * Available in various magnetic forces.

Request for a quote

SAPLI SOLUTIONS

Spain

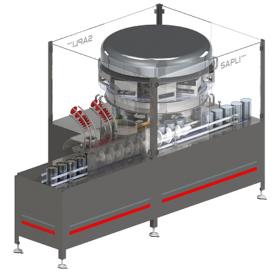

Continuous or Intermittent motion highly Accurate Rotary Powder Filler is a suitable solution for a wide range of powdered and granule products to be filled with medium and high production rates. One or more filling stations options, depending on product flow characteristics and a packaging formats. Rotary machines are available with over turrets of 12 to 48 pockets, with outputs up to 400 containers per minute. These can be integrated with gross or tare and gross check-weigher feed-back systems.

Request for a quote

SAPLI SOLUTIONS

Spain

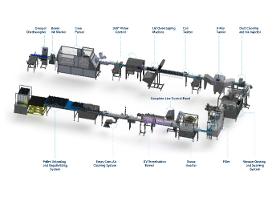

Stand-alone machinery and key turn projects for fully-automatic multiformat filling and packaging lines. Machinery for powdered and solid products, such as Powdered Milk, Infant Formula, Sport Supplements, Coffee, Snacks, Confectionery Products and others in metal tin cans, plastic containers, glass jars and carboard tins.

Request for a quote

SAPLI SOLUTIONS

Spain

• Vacuumgassing seamers from Sapli are high performance solution for low and high production speeds. • The modular principle allows adding new seaming stations in the future, in case of increasing of production capacities. • Suitable for the seaming and vacuum gassing products in tinplate, aluminium, paperboard and plastic cans packaging across a wide range of industrial sectors. • Perfect sealing technology with adjustable working speeds. • Easy and intuitive format change. • Adjustable levels of residual O2 level after seaming, depending on the product requirements for guaranteeing a long shelf-life of the product. • Vacuum and gassing pressures are configurable, and can be monitored on each can seaming cycle • Guarantying the highest food security and produced with EU Declaration of Conformity. • Suitable for the wide range of tin cans formats, heights and diameters. • Multiformat principle allows working with lots of packaging formats at the same machine.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Sheet metal - Import exportNumber of results

4 ProductsCountries

Company type