- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plate exchangers

Results for

Plate exchangers - Import export

AGGREKO CANNOCK

United Kingdom

We have all types of industrial heat exchangers, including: plate and frame shell and plate shell and tube fin/fan They’re refinery-grade, thoroughly cleaned, pressure tested and certified contaminant-free before each use. Capable of handling temperatures from -50ºC to +300ºC, they can also accept volatile gases and liquids, high pressures (up to 40 barg), hydrocarbons, sea water, effluent and brine. With a wide range of supporting ancillaries we can connect our heat exchanger units into any system design with minimum disruption. Heat exchanger hire with expert service support – every time Whether you’re facing emergency bottlenecks, turnarounds or seasonal cooling needs, our process engineers will work closely with you to find the best solution. They’ll visit your site, assess your needs, then design and size your project using their experience, simulation software and stream physical properties. We can also assess the performance of existing heat exchanger

Request for a quote

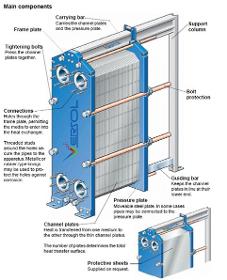

VERSOL LTD (VERSOLGROUP)

United Kingdom

The Versol standard range of heat exchangers are is developed to generate hot water/cold water efficiently with/without the need for storage. VERSOHEX can be used with storage tanks to heat up the stored water or can be inline in the system to produce hot/cold water directly. VERSOHEX can be in three ranges as below VERSOHEX-IM – Immersion Heat Exchangers VERSOHEX-PL- Plate Heat Exchangers VERSOHEX-ST- Shell & Tube Heat Exchangers VERSOHEX-IM Range VERSOL are specialized in the design and manufacturing of Immersion HeatExchangers for deferent applications. VERSOL Immersion Heaters are capable to fulfill customer requirements in Heating or Cooling of liquids. VERSOL offers mainly two type of Immersion Heaters. Immersion Heaters are designed to use with VERSOTHERM Calorifiers or Standard models are available to use with different Calorifiers Tanks. Material and size selection should be taken care after confirming the Calorifiers tank material and dimensions. 1.

Request for a quote

TECHTRON

United Kingdom

We offer a state-of-the-art contract chemical blending facility comprising four five-tonne bespoke vessels that have been designed especially for us. Some of the vessels are mounted on load cells for increased accuracy and all are controlled from a fully-automated PLC control panel. The liquid blending tanks have been constructed from food grade 316 stainless steel and are fitted with fully-automated cleaning in place (CIP) regimes for hygiene purposes. Two of the vessels in situ have the unique capability of handling exothermic chemical reactions with inline plate heat exchangers and temperature control systems. These vessels are also fitted with direct acid and base feeds to minimise exposure of the liquid blending personnel. The chemical blending tanks can be fed by a double filtered UV treated mains water feed system, or alternatively, from a full deionised water plant complete with reverse osmosis that is generating water to a pharmaceutical specification.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Plate exchangers - Import exportNumber of results

3 ProductsCompany type