- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- surface treatment - machinery and equipment

Results for

Surface treatment - machinery and equipment - Import export

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the atmospheric pressure plasma system PlasmaBeam Mini, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 3 - 5 mm, substrates can be treated locally with precision. In contrast to the Plasmabeam devices, the PlasmaBeam Mini is designed for laboratory use. The PlasmaBeam technology enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam PC atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam PC is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 1440 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 1440 litres of this plasma system offers enough space to serve series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Parylene is the short name for the polymer group of poly-para-xylylene. Parylene coatings offer a wide range of benefits. Parylene ... are fully conformal: i.e. they adapt to complex substrate contours such as sharp edges, drill holes or blind holes are pinhole-free from a film thickness of approx. 0.5 µm. are chemically insoluble and resistant to a wide range of chemicals. have very good barrier properties against moisture and chemicals. have a high dielectric strength. have dry lubricating properties (low coefficient of friction). are hydrophobic: contact angle of H2O between 92 ° and 98 °. are transparent between 90 and 96 % in the visible wavelength range (depending on type). are biocompatible: types C and N parylene can be deposited, which can be certified according to USP Class VI, ISO 10993 and FDA.

Request for a quote

FÖHRENBACH GMBH

Germany

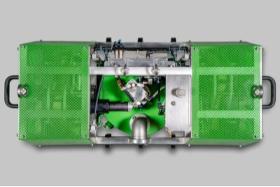

The machine structure with solid base plate is extremely compact and stable. All necessary components are integrated in the machine housing: mechanical axes, pneumatic components, control with drive electronics and mounted 12 "touch display. Depending on the desired version, the F-Décor 305 can produce surface patterns like circular grainings, côtes de Genève, engravings or decorative millings on mechanical watch parts. The machine guarantees high precision and high productivity. The F-Decor 305 is delivered ready for connection with either 1 or 2 working spindles.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 45 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 45 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam DUO atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

A cost-effective process for activating plastic and elastomer surfaces is treatment with the APC500. Using air as the process gas, large surfaces can be activated under atmospheric pressure. An arc is ignited between two electrodes in an inhomogeneous field. The voltage is about 10,000 V. In the discharge zone, the air flowing through is ionised. The plasma is blown out of the electrode area by the air flow. The substrate can now be treated in the emerging corona. A strip several centimetres wide is treated in the corona. With several parallel plasma generators it is possible to treat surfaces. Due to dangerous voltage potential, PlasmaAPC 500 is only suitable for non-conductive materials. PlasmaAPC 500 is suitable as a pre-treatment unit for the following processes: Bonding, printing, painting. The following surfaces can be treated with PlasmaAPC 500: Plastics, rubber, ceramics, glass.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tretra 320R low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 320 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Atto low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 10.5 litres of this plasma system offers enough space to serve laboratory and also small series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ...

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

A cost-effective process for activating plastic and elastomer surfaces is treatment with the PlasmaAPC 500 DUO. Using air as the process gas, large surfaces can be activated under atmospheric pressure. An arc is ignited between two electrodes in an inhomogeneous field. The voltage is about 10,000 V. In the discharge zone, the air flowing through is ionised. The plasma is blown out of the electrode area by the air flow. The substrate can now be treated in the emerging corona. A strip several centimetres wide is treated in the corona. With several parallel plasma generators it is possible to treat surfaces. Due to dangerous voltage potential, PlasmaAPC 500 DUO is only suitable for non-conductive materials. PlasmaAPC 500 DUO is suitable as a pre-treatment unit for the following processes: Bonding, printing, painting. The following surfaces can be treated with PlasmaAPC 500 DUO: Plastics, rubber, ceramics, glass.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 30 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 34 up to 50 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Nano low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 18 up to 24 litres of this plasma system offers enough space to serve laboratory and also series production. Plasma treatment in low-pressure plasma is a proven technique for controlled ultra-fine cleaning, improvement of adhesion (activation and etching) and coating of thin layers on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues. Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Pico low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 5 up to 8 litres of this plasma system offers enough space to serve laboratory and also series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Zepto low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 1 - 4 litres of this plasma system offers enough space to serve laboratory and small series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ...

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam DUO atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Femto low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 2 to 3 litres of this plasma system offers enough space to serve laboratory and small series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 2800 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 2800 litres of this plasma system offers enough space to serve series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam QUATTRO atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam QUATTRO is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the atmospheric pressure plasma system PlasmaBeam RT, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 120 mm, substrates can be treated locally with precision. With our new product, the PlasmaBeam RT, there is now the perfect solution for fast, efficient and wide in-line plasma treatment of 2D surfaces. The RT can be perfectly integrated into existing production lines and thus enables the automated cleaning and activation of various components and web-shaped materials. We create the possibility of up to 120 mm wide plasma treatment, with the usual consistent quality and effectiveness of atmospheric pressure plasma systems from Diener electronic.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 150 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 150 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 100 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 100 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Impregnation systems to close micropores in metal castings as well as in copper, aluminium or magnesium alloy castings. The parts to be impregnated are fixed in baskets. The latter are transported by a special crane system as well as with reservoir roller conveyors. Excess material is removed by centrifuging of the baskets. The impregnating agent remaining in the pores in fluid form is hardened by heating in a hot water bath. The process sequence runs fully automatically under a microprocessor control.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Sustainability is very important to us, so we buy back existing plants, upgrade and adapt them to customer needs Siempelkamp machines and plants go through a sustainable life cycle We buy back machines and entire plants that were in operation and adapt them to the individual needs of our customers. We modernize used plants and upgrade them to current industry-standards with increased performance. Siempelkamp offers you a wide range of pre-owned machines and plants When purchasing a plant that has been in operation, professional and cost-effective implementation of all measures - from dismantling to commissioning - are decisive processes for project success. We offer you second-hand plants for the production of particleboard, MDF and OSB with continuous press systems from well-known brands such as Siempelkamp, Küster, Bison, and Metso.

Request for a quote

AFS ENTWICKLUNGS + VERTRIEBS GMBH

Germany

The effect achieved by the corona treatment is an increase in surface tension to values between 38 to 60 mN/m. Since the surface tension is caused by dispersive and polar interaction components the introduction of polar functional groups in particular increased the polar component of the surface tension.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of Germany’s largest independent gear, pinion and shaft manufacturers. We manufacture according to customer drawings and supply renowned customers from a wide variety of industries. We also supply renowned customers on an international level with our products for mining technology. Here is an overview of our production possibilities: Internal toothed rings hardened and grinded Module up to 20 mm Diameter 100 to 1,800mm Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Interlocking shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible We manufacture for different customers: mining, rail, wind power, shipping, industry and special machinery. Production is carried out according to customer drawings and standards. Further information in the first interview. We look forward hearing from you.

Request for a quote

KAMAT GMBH & CO. KG

Germany

We have specially developed the KAMAT Gekko 350 in order to clean large steel surfaces, for example ships, or large tanks, rapidly and without building scaffolding. Key technical advantages of the high-pressure surface cleaner are the thought-out combination of natural magnets and chain drive, as well as controllable high-pressure nozzles. The complete high-pressure system is remotely controlled conveniently and safely.

Request for a quoteResults for

Surface treatment - machinery and equipment - Import exportNumber of results

29 ProductsCountries

Company type