- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding robots

Results for

Welding robots - Import export

QUELLTECH GMBH

Germany

QuellTech Solution For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position. The QuellTech 2D-Laserline Sensor is specially prepared to the highly disturbing ambient light from the weld process. It can be cooled and protected from weld spatter, so this model proves to be particularly adequate for operation in the harsh environment of the welding process.

Request for a quote

NOVELTY STEEL

Turkey

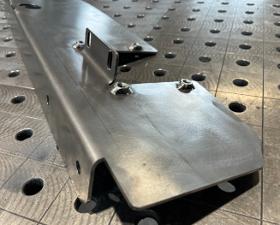

Carbon Steel and Stainless Steel Robot Laser Welding Part Manufacturing

Request for a quote

WILH. KÄMPER GMBH U. CO KG

Germany

We employ welding robots to join complex metal wire parts made of steel or aluminium to form an assembly. This in turn leads to complex bent wire components for the automotive industry, such as brackets for cushioning frames, and eyelet fastenings.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

High quality, productive longitudinal seam welding calls for the utilisation of advanced, superior technology. This enables us to us to protect and expand our market position despite increasingly fierce competition. Our ELENA® longitudinal seam welders provide unsurpassed technology for welding of longitudinal metallic seams.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

We specialize in the custom fabrication of sheet metal components to the exact specifications specified in our customers' drawings. Our advanced technologies, including laser cutting and precision CNC bending, ensure accurate production to customer specifications. In addition, our robotic welding and grinding stations ensure high-quality surface finishes and consistency of production. Thanks to our dedicated CNC surface finishing centre, we can achieve the required material readiness for surface finishing. Our commitment is to deliver products that not only meet, but exceed the expectations set out in the customer's drawings, ensuring the satisfaction and reliability of every part produced.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in manufacturing sheet metal components according to individual customer requirements and specifications. We utilize state-of-the-art technologies, including laser cutting, CNC precise bending of sheet metal, robotized welding workstations, robotized grinding workstation, and CNC center for rounding and grinding the surface of sheet metal. These advanced tools enable us to deliver products of the highest quality and precision. Whether it's intricate designs or specific dimensions, our technological capabilities allow us to efficiently and reliably meet even the most demanding customer requirements.

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in the production of welded metal constructions tailored to customer requirements. The materials we use include steel, aluminum, and stainless steel. Our processes incorporate cutting-edge technologies such as laser cutting, CNC sheet metal bending, robotic welding, and robotic grinding. In collaboration with our partners, we also address surface finishing solutions, including powder coating, hot-dip galvanizing, electroplating, pickling, and passivation. We take pride in the quality and precision of our products, ensured by these technological innovations. With our focus on technological advancement, we are capable of meeting even the most demanding requirements of our customers.

Request for a quote

ELEKTRON SP. Z O.O.

Poland

Nowadays, technology allows the use of machines that successively improve production while increasing the quality of services. The PANASONIC welding robot is a reliable machine used for the serial production of metal parts. The welds made by the robot are durable and aesthetic at the same time. The use of a welding robot ensures remarkable weld accuracy. The use of a welding robot not only significantly speeds up the serial production process but also guarantees durable welds for years. Welding robots are also perfect for the production of metal elements for furniture. The quality of the weld made by the welding robot stands out significantly compared to the weld made by hand, as it eliminates any unevenness and prevents the formation of craters. One of the many advantages of the welding robot is its ability to determine the thickness of the weld depending on the production of the product for which we programme this modern machine. As we mentioned before, welding

Request for a quote

ASP

France

The very different requirements created by diverse welding techniques mean that specific products have to be specially developed. The industrial fabrics we use have specific coatings that leave the cover flexible but resistant to spatter and weld splashes. Their para-aramid base has excellent mechanical strength. Production tooling protection is a necessity. ASP offers a wide range of protective covers for all types of welding guns, regardless of the welding technology involved (pneumatic, hydraulic or electric motor).

Request for a quote

SINOP SMP

Czech Rep.

For high volume production, but also for smaller batches MIG/MAG welding TIG (WIG) welding with wire feeding MIG soldering with an additional material CuSi Fixture design and development in house

Request for a quote

ASP

France

A unique assembly of special textile panels and various closing/attachment systems to guarantee: Ultra-fast and simplified installation and removal without the need for tools. Efficient and long-lasting protection for your equipment. Improved MTBF (Mean Time Between Failures) and MTTR (Mean Time To Repair) thanks to quick access to the welding gun, thereby saving valuable time during maintenance operations. Optimized operating costs through easy replacement of worn parts only. They are untearable and electrically insulated, and are guaranteed halogen-free and silicon-free. The coatings on the two sides prevent the fabric from soaking up any water or oil in the event of leakage. Limited splatter adhesion and M1 fire rating classification complete the high level requirements.

Request for a quote

SRI - SAINT-REMY INDUSTRIE

France

We produce arms for welding guns in pure copper, aluminium bronze, tin and lead bronze as well as brass. Pieces are delivered as-cast, rough or fully machined.

Request for a quote

PEROZENI SRL

Italy

For years, Perozeni S.r.l. has been active in the field of medium-heavy mechanical and metalworks, constructing systems, machinery or parts of machines (for a wide range of sectors), even of exceptionally large size, on commission for its clients. The company’s technical personnel are able to perform complicated procedures of mechanical metalwork complying with the clients’ project specifications, placing great attention on the quality of the raw materials used and on the complete realization of the product.Every single piece is made with extreme skill, using qualified personnel subject to continuous training, certified by the main organizations recognized in the sector. Our workers have acquired years of experience in the company and are specialized, having obtained the qualification of welders according to standard UNI EN ISO 9606-1:2013. The company has also certified its system of welding activities according to standard UNI EN ISO 3834-2:2006.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

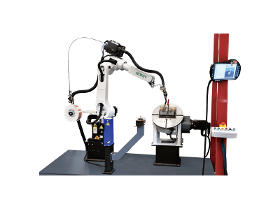

ProArc and HIWIN bring robot application to a intelligent and remarkable milestone in welding industry through the new weld robot system. System comes with full package including Cut wire Work station w/Multi Task Modular cells To define robot in the COORD export system Pass [Position Register] function to make function infinity

Request for a quote

RILLEX S.R.O.

Slovakia

These protector sleeves are made-to-measure and are antistatic as well as oil and water repellant. They are made of long life durable material so it protects longer. It is washable. The protector can include peek holes with visors, can be made of combined materials.

Request for a quote

KEY PLANT AUTOMATION LTD

United Kingdom

High performance plug and weld robotic welding cells. Cost effective, production boosting and floor saving, the pay by the hour robotic welding cells are delivered ready to weld, simply plug and go – it’s as easy as that! All cells are two station, Loading whilst welding, and are protected by a light barrier and safety fence. Hassle free delivery – straight to your facility and workshops. With their one lift, easy to transport modular design, the robotic welding cells are delivered direct, hassle free to your facility. Pay by the hour rental Ready to use, plug and weld Cloos welding technology One lift, easy to transport Save production floor area

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding / handling robot FD-B6 with integrated cable routing and further developed design is designed for all welding tasks and payloads up to 6 kg. Even the connections and cables required for the SynchroFeed welding process are pre-installed. Due to its outstanding arm length, it is particularly suitable for large work areas • Higher clock speeds for highest industrial speeds • Slim design: Integrated wrist motors prevent malfunctions from devices and workpieces. • User-friendly: Integrated supply lines prevent faults behind the robot arm. • Suitable for up to 6 kg payload capacities. Ideal for corresponding handling applications. Number of axes: 6 Max. payload capacity : 6 kg Working Range (P point): R 1445 mm Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3132 W Weight: 278 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding robot FD-V8L with a refi ned design can handle all welding tasks and payloads of up to 8 kg. Due to its outstanding arm length, it is particularly suitable for large working areas. Faster cycle time: Designed for highest industrial speeds. Slim Design: Thanks to the slimmer lower arm design, less rotary motion is needed to reach the working position, thus preventing collisions with jigs and workpieces. User-friendly operation: Even the cables required for SynchroFeed are integrated into the lower arm, which prevents interference behind the robot arm. Stronger structure: Maximum payload now up to 8 kg. The use of different torches and sensors is possible. The main technical specifications at a glance: Number of Axes: 6 Max. payload capacity: 8kg Working Range (P-Point): R2006 mm Positional repeatability: +/- 0,08 mm Drive System: AC Servo Motor Drive Power: 5000 W Weight 273 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4S from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1435 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3550 W Weight: 189 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding robot, FD-V8, is equipped for all welding tasks and for load capacities of up to 8 kg. Thanks to integrated cable routing, the FD-V8 can still weld much more interference-free than any other robot in its class. It is 15% faster and the cycle times are accordingly shorter - ideal for maximum productivity. Interference-free: Interference-free welding thanks to integrated cable routing SynchroFeed-ready: Cables for the SynchroFeed / Servo-torch system can be integrated into the robot. Robot distances: Integrated cable routing enables reduced distances between the robots. Increased payload capacity: Higher load capacities of up to 8 kg. Higher performance: Up to 15% higher speeds. The main technical specifications at a glance: Number of axes: 6 Max. payload capacity: 8 kg Working Range (P point): R 1437 mm Positional repeatatbility: +/- 0.08 mm Drive System: AC Servo Motor Drive power: 3016 W Weight: 140 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding / handling robot FD-B6 with integrated cable routing and further developed design is designed for all welding tasks and payloads up to 6 kg. Even the connections and cables required for the SynchroFeed welding process are pre-installed. Thanks to higher process speeds and shorter cycle times, the FD-B6 fulfills all requirements for the most demanding handling tasks. • Higher clock speeds for highest industrial speeds • Slim design: Integrated wrist motors prevent malfunctions from devices and workpieces. • User-friendly: Integrated supply lines prevent faults behind the robot arm. • More stable construction: 1.5 times the load capacity for welding tasks with different ranges. Number of axes: 6 Max. payload capacity : 6 kg Working Range (P point): R 1445 mm Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3132 W Weight: 145 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V6LS from the FD series impresses with its slim design and an expanded degree of freedom, which enables a constant torch orientation when immersing in tight work spaces. Compared to the V6S, the V6LS has an extended arm, which is why the range is increased again. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2006 mm Max. payload: 6kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6000 W Weight: 316 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V6S has an extended degree of freedom which enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several of the FD-V6S robots can be placed closer together in manufacturing cells, which simplifies an increase in the number of robots per component. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1427 mm Max. payload capacity: 6 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3600 W. Weight: 178 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4LS from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. In addition, the FD-B4LS offers an extended arm compared to the FD-B4S and thus a larger working radius. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2008 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 5650 W Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V20S from the FD series is the optimal robot for medium-heavy loads. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1710 mm Max. payload: 20kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6600 W. Weight: 321 kg

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

Clean and high-quality cutting edge Increased productivity through reduced scrap and labor costs Low cost maintenance and consumables Maximum system flexibility thanks to robot mobility Designed to run without human intervention Easy and efficient to program, even complex paths and shapes Provides better precision, customization, speed and safety Optimal material utilization Robotic Cutting Software; Parameters automatically adjusted regarding to material and thickness. Calculated tool-paths and robot movements can be verified with simulation. Robot paths and laser parameters can be easily calculated on the offline CAM and simulation software. Step data can be loaded, and paths can be determined from edges or faces of CAD data

Request for a quote

KUNLUN COMMUNICATION & INDURSTRIAL NETWORKING INTEGRATION CO., LTD.

China

KL1500-B-6 is the earliest painting robot launched by the company. With a payload of 6 kg and a reach of 1500 mm, it is generally integrated with various non-standard turntables or hanging equipment to form work stations. The figure shows the hanging line tracking and painting solution provided for a customer. It not only significantly reduces labor cost but also improves the yield.

Request for a quote

KUNLUN COMMUNICATION & INDURSTRIAL NETWORKING INTEGRATION CO., LTD.

China

Instructions for Accessories Welding equipment 1. Max. operating distance of teaching device and robot electric cabinet The standard cable length of the teaching device is 5 m; the standard cable of the robot and electric cabinet is 3 m long. 2. Max. distance between robot and electric cabinet This distance is the length of the straight-through cable. It is generally 6 m by default. Other lengths can be customized.

Request for a quoteResults for

Welding robots - Import exportNumber of results

96 ProductsCountries

Category

- Welding robots (36)

- Industrial robots (17)

- Steels and metals - welding and brazing (10)

- Assembly robots (8)

- Finished Metal Products (6)

- Unloading and loading ramps (5)

- Welding work - steels and metal (5)

- Laser - cutting and welding machines (4)

- Welding, electric - equipment and supplies (3)

- Concrete mixers (2)

- Electron beam welding - equipment (2)

- Painting robots (2)

- Pallets (2)

- SMALL METAL PARTS (2)

- Silicones (2)

- Armchairs (1)

- Autogenous welding machines (1)

- Automation - systems and equipment (1)

- Bending - steels and metals (1)

- Compactors and crushers (1)