- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding inspections

Results for

Welding inspections - Import export

BALTEAU NON DESTRUCTIVE TESTING

Belgium

Designed to perform welding inspections on cylinders up to a diameter of 250mm, the AIS231 is a real time system designed to be automated that can also be installed with an ADR module (depending on the client requirement). It is equipped with a shielded cabinet for up to 450kV depending on the power of the generator installed, a flat panel, a 2 axis manipulator, a motorized door, and more. To ensure a great and easy environment of work, the control desk will carry a 19’’ computer with the Inspection suite of software installed allowing the automation of the process which will fastened the everyday inspection.

Request for a quote

XIRIS AUTOMATION INC.

Canada

Enable personnel to monitor the weld torch position and condition during set-up and in production. The SeamMonitor™ System is a complete inspection system and includes a Xiris open arc weld camera, industrial HMI controller, preloaded with SeamMonitor™ software, and various options to suit your application. SeamMonitor™ enables operators to obtain seam alignment and other simple weld inspections as well as having a clear image of the weld arc and its immediate environment to allow for weld process monitoring and ongoing adjustments to the weld process.

Request for a quote

XIRIS AUTOMATION INC.

Canada

A precision laser-based 3D inspection system to detect quality issues related to forming & welding processes on larger diameter tube or pipe mills. Several models of the WI3000 are available depending on the Field of View (FOV) requirements, type of Mill and size of the Tube/Pipe being run during the welding process. The WI3000 system is particularly suitable for a wide range of HF Mills making tube/pipe from OD >12 mm with bead sides up to 28mm wide. Other applications also include Longitudinal or Spiral Pipe manufacturing.

Request for a quote

XIRIS AUTOMATION INC.

Canada

A precision laser-based 3D inspection system for detecting quality issues related to the forming, welding and scarfing processes on smaller diameter tube or pipe mills. Xiris’s proven laser-based vision system technology with high resolution, fast data capture and analysis rates provides real-time detection of defects down to 0.015 mm in size. Defects inspected include mismatch, undercut, sunken welds, bead height, deflection, freeze line and scarfing defects. Several models of the WI2000 are available depending on the Field of View (FOV) requirements, type of Mill and size of the Tube/Pipe being run during the welding process. Suitable for tube / pipe with Outside Diameters of 5-200 mm (0.2-8″) with a maximum Weld Bead Width of about 10 mm (0.4″).

Request for a quote

XIRIS AUTOMATION INC.

Canada

The XVC-1000e is designed to meet the needs of end users or systems integrators who are looking for fast, easy integration of a weld camera to their welding process. Featuring the XVC-1000 camera in a robust, industrialized housing, the XVC-1000e comes complete with integrated light sources, motorized focus, air or water cooling and a protective spatter window. The XVC-1000e is monochrome, the XVC-1100e is color.

Request for a quote

XIRIS AUTOMATION INC.

Canada

The Xiris XVC-1000/1100 Weld Camera combines a spectacular 140+ dB High Dynamic Range capability with power over Ethernet, a full suite of welding-specific imaging software tools, and a host of unique features to provide unprecedented image quality of a variety of welding and laser processes. The XVC-1000 is monochrome and the XVC-1100 is color.

Request for a quote

XIRIS AUTOMATION INC.

Canada

The Xiris XVC-700 packs high performance into its slimline package. Featuring High Dynamic Range (HDR) in excess of 140db, angled optics head configurations ranging from 0° to 90° and, GigE Interface with PoE, the all-digital Xiris XVC-700 takes weld imaging where it has never been able to go before. The straight camera weighs 89g, and squeezes into a slight 22 x 22 x 107mm frame before optics are mounted.

Request for a quote

QUELLTECH GMBH

Germany

Initial Situation: Inspection of a laser weld seam for pores and geometrical anomalies The production of a client in automotive industry is subjected to extremely stringent quality requirements. This is valid particularly also for the precision of laser weld seam of fine mechanical work. 100% inline supervision is required for the following task: A laser weld beam (width ca. 200µm) has to be verified with respect to the presence of pores and geometrical anomalies. Camera inspection performed until now turned out to be not stable. Therefore the client is forced to implement an improved monitoring process. The challenge The resolution required amounts to 4µm. The high gloss finished material and glossy laser weld seam may give rise to reflections, and the space for installation is restricted. A low form factor for the monitoring equipment is imperative.

Request for a quote

QUELLTECH GMBH

Germany

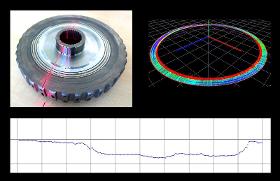

Rotationally symmetrical driving gears in a line producing for automotive industry are mutually connected by electron beam welding. The camera inspection carried out until was not able to assess the quality of the weld seams at the required precision. Non-contact laser measurement system Particular Challenge: As the welding seams show a high reflectivity and are located at a position hard to access, inspection is difficult, all the more so as they dispose of a width of only 500µm. Therefore it is quite a challenge for the laser measurement system. The QuellTech solution: A QuellTech Laser Scanner Q4-5 with extremely small shape factor and high resolution proved to be perfectly suited for this application. In order to suppress reflections from elements in the surroundings, a particular algorithm has been integrated. Furthermore, this laser measurement system features a particularly adapted laser wavelength and an ultrafine laser line.

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed grade 1.4301, 12-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed grade 1.4301, 10-1.5 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed ground grit 240, grade 1.4301, 10-1.5 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed grade 1.4301, 10-1 mm

Request for a quote

STAPPERT INTRAMET SA

Belgium

Tube round welded,without inspection, not annealed ground grit 240, grade 1.4301, 10-1 mm

Request for a quote

RUDOLF UHLEN GMBH

Germany

• The mesh visor is made of galvanized wire cloth • It shields the face against radiant heat • The mesh visor has a window opening for lenses with the dimensions 60 x 120 mm • Among others, blue inspection glasses, green welding glasses, or clear glasses can be utilized in the window opening • The lenses are securely clamped in the lens frame by two steel springs • Like the other face shields, the mesh visors are also attached to an aluminium hard hat bracket (e.g. GFKHH003) • The blackened inner side ensures good visibility and prevents the wearer from being blinded by glare

Request for a quote

RUDOLF UHLEN GMBH

Germany

• The mesh visor is made of galvanized wire cloth • From the outside the mesh visor is covered with aluminised fabric • It shields the face against radiant heat • The mesh visor has a window opening for lenses with the dimensions 60 x 120mm • Among others, blue inspection glasses, green welding glasses, or clear glasses can be utilized in the window opening • The lenses are securely clamped in the lens frame by two steel springs • Like the other face shields, the mesh visors are also attached to an aluminium hard hat bracket (e.g. GFKHH003) • The blackened inner side ensures good visibility and prevents the wearer from being blinded by glare

Request for a quote

MIX SRL

Italy

Properties • no screws, pull-in sleeves or stiffeners in contact with the product on which the product can deposit • all parts that come into contact with the product are suitable for contact with food • continuously welded seams • hinged, lateral inspection hatch, which closes practically without dead space, with replaceable and washable seal • parts in contact with the product made of stainless steel with material certificate 3.1 according to EN 10204 • available for applications in positive or negative pressure or equipped with a fan

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IMS - INTEGRATED MECHANIZATION SOLUTIONS BV

Netherlands

We build and develop high precision product manufacturing machines for the medical industry. With a proven track record of 20+ years we have gained quite some knowledge and experience. Whether you are looking for product assembly, laser marking, laser welding, visual inspection, feeding, EOL, flow and leakage testing or anything else, we are your precision partner. Your process, product and business case is our guiding principle. We know how to automate like no other. In fact, we know how to automate very accurately. Automation at IMS goes down to micron scale. We build production lines from low to high volume, depending on your demand. We are flexible to the needs of your project and deliver a fast budget indication quote. Showing feasibility of your production process.

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

This extremely robust flat-panel detector was specially designed for mobile use and the harsh conditions of industrial radiography and can be used with X-ray and gamma sources. The one-piece aluminum housing ensures maximum protection against external influences. It is also dust and waterproof and classified as IP67 according to IEC standard 60529. With its active area of 23.3 x 29.1 cm, excellent contrast and uniquely high resolution thanks to a pixel pitch of 76 µm, even the most demanding inspection tasks can be mastered. - Weld seam inspection - Pipe inspection, corrosion inspection, erosion inspection - Crack detection - Casting inspection

Request for a quote

DÜRR NDT GMBH & CO. KG

Germany

Portable high resolution CR scanner for all NDT radiography applications - weld inspection, profile images and aerospace Unique 30 μm basic spatial resolution – BAM-certified Scans flexible imaging plates up to 35 cm in width Widest range of applications thanks to TreFoc Technology Intuitive handling & easy transition from film Portable and compact (17.5 kg) What does TreFoc Technology mean and how does it work? TreFoc Technology is the name for the our new laser focussing technology, uniquely in systems from DÜRR NDT. With TreFoc the laser beam is adjusted perfectly to give optimal image results and the highest signal-to-noise ratio in any application. Inside the laser tube, an iris diaphragm adjusts the laser beam diameter. Since the perfect laser beam diameter can be selected for each object and image type, optimum results for any particular application can be easily achieved. Regardless of the application – high-resolution image or low-exposure c

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

High quality control, no burr and scratch on surface and trimming edge Process Design moulds→ confirm samples→ purchase material→ blanking→ punching→ welding/bending→ forming→ surface treatment→ Inspection→ assemble products→ Package We can produce and process stamping parts (https//www.frimaparts.com/precisionmetalstamping/) according to your requirements. Lead time for samples in 15days. COC, Test Report, RohS , plating report, coating reports, is available !

Request for a quote

BALTEAU NON DESTRUCTIVE TESTING

Belgium

Shielded cabinet for x-ray inspection of welded samples and castings The AIS228L is the bigger version of our well know AIS228. It is still a compact equipment that provides you with numerous advantages. A wide variety of samples as well as different thicknesses can be inspected with this unit. This shielded cabinets includes, a irradiating source, a directional X-ray generator from the very well-known and efficient Baltospot range. These cabinets are generally made of a steel structure with lead reinforcement to assure a proper shielding against radiation outside of the confined area («sandwich» type assembly: steel-lead-steel). This user-friendly equipment can be very easily operated with a maximum safety.

Request for a quote

BALTEAU NON DESTRUCTIVE TESTING

Belgium

Shielded cabinet for x-ray inspection of welded samples and castings The AIS228 is a very compact equipment that provides you with numerous advantages. A wide variety of samples as well as different thicknesses can be inspected with this unit. This shielded cabinets includes, as irradiating source, a directional X-ray generator from the very well-known and efficient Baltospot range. These cabinets are generally made of a steel structure with lead reinforcement to assure a proper shielding against radiation outside of the confined area («sandwich» type assembly: steel-lead-steel). This user-friendly equipment can be very easily operated with a maximum safety.

Request for a quote

HIDROMEC SRL

Italy

The cylinders used in lifting equipment must be designed in such a way that their weight is as low as possible. For this reason, welded constructions are mainly used, with piston rods made of tubes, often of special materials, which make it possible to reduce wall thickness while maintaining the required load limits. Particular attention must be paid to the welds, which are often inspected with ultrasound, as the breakage of a welded part can easily lead to very serious damage. HIDROMEC develops hydraulic cylinders and systems for hydraulic lifting equipment that are reliable, durable and in compliance with specific industry standards.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For high voltage energy supply/distribution Welding (incl. welding on bolts) Pressure testing with SF6 gas Full dimension check (providing DXF file) X-ray inspection of welding seams where possible, inspection of all other seams with ultrasound Mechanical engineering

Request for a quote

JME LTD

United Kingdom

JME Advanced Inspection Systems has a reputation as the market leader for the design and manufacture of high quality inspection systems, this includes our range of Pipeline Crawlers used by the ‘Non-Destructive Testing’ industry. For over 30 years, JME Pipelines Crawlers have been continually improved and updated to produce panoramic radiographs of the highest quality. Our range of systems are designed to inspect circumferential butt welds in new pipelines, such as oil and gas transmission pipelines, from 6” to 72” (15.24cm to 183cm). As a self-contained and self-powered exposure vehicle, they are ideal for a vast range of NDT applications both on and off shore. Over the past 30 years, JME has built its reputation on innovation, quality, service, and commitment to our clients. As a company, JME thrives on customer satisfaction, which is why many of our customers have been using our services for nearly 30 years.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The R-Series robots from Kawasaki can be used in a variety of applications and industries like welding, material removal, machine tending, inspection, dispensing and assembly. This high class technology has a total horizontal reach of 1,925mm and vertical reach of 3478mm. This cutting edge technology also boasts of its fast speed and the maximum speed of this is 13,100 mm/s.

Request for a quote

KAWASAKI ROBOTICS GMBH

Germany

The R-Series Robots from KAWASAKI ROBOTS can handle a maximum workload of 30 kilograms and speeds up to 13,400 mm/s. The 2.1-meter horizontal and 3.697-meter vertical reaches of the R-series makes it usable for assembling, inspecting, dispensing, welding, material handling and removing, machine tending, and other applications within a wide range of various industries. With these, the R-series from KAWASAKI sets the bar for small to medium duty industrial robots.

Request for a quote

DONGGUAN SANWEI FLEXIBLE AUTOMATIC EQUIPMENT CO., LTD

China

Sanwei good welding table is a new type of advanced and flexible process equipment with an integration of welding, assembling and inspection. it has the same applicability as 3D flexible and modular welding table. Thanks to the board with it to hang available tools, things can be quickly picked and put, which can improve the work efficiency of 50% -80% compared with traditional welding table. use with standard 3D clamping fixtures during positioning processing leads your work to be simple and easier. The surface flatness up to 0.05/1000mm while hardness up to 38-45HRC, which allow it used as a product inspection platform. Meanwhile, accurate positioning, convenient disassembly and high applicability, it also provides a standardized, green, and new concept in welding line, completely changes the face of traditional welding workshop. It is welder's best useful friends, a symbol of environment- friendly and provides a strong guarantee for the company's 7s work.

Results for

Welding inspections - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Monitoring and control equipment (6)

- Protective and work clothing (3)

- Automation - systems and equipment (2)

- Mechanical engineering - custom work (2)

- Casting, steel (1)

- Filtering equipment and supplies (1)

- Hydraulic equipment (1)

- Non-destructive tests (1)

- SMALL METAL PARTS (1)

- Steels and metals - welding and brazing (1)

- Testing equipment (1)